High-end solutions and machines

Wind tower construction

Voortman offers high-end machines and solutions for different types of wind tower production. We distinguish two types of production methods. One type of production is based on bolted connections and the other on welded rolled shells.

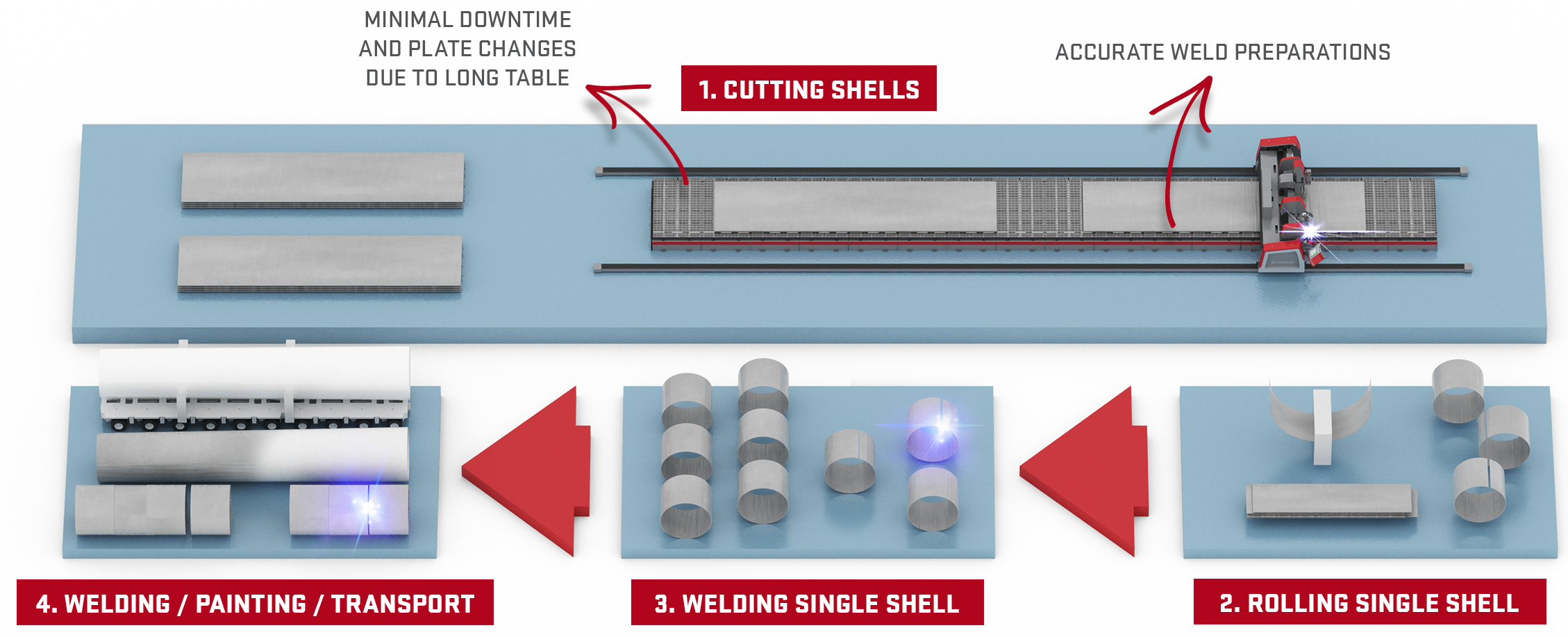

See below which challenges we can solve for the welded rolled shell production process. This production process focuses on created weld preparations on all sides of a large plate, whereafter this plate is rolled in a circle and welded together.