Fiber laser cutting - why it boosts your output

BY STEF ROHAAN, PRODUCT MANAGER, VOORTMAN

Laser cutting has fundamentally transformed the way thicker steel is processed across the fabrication industry. Where traditional methods like plasma or oxy-fuel cutting once dominated, laser technology now offers unmatched precision, speed, and efficiency, even in heavier materials.

At the end of the day, it’s not just about cutting sheets, it’s about how much finished product you can move downstream. In this article, I want to walk you through five areas where fiber laser technology really makes a difference in plate processing - and why they matter on the shop floor.

- BENCHMARKING PERFORMANCE & AUTOMATION

We set the bar by showing what true lights-out automation and consistent output look like.

- THE HIDDEN BOTTLENECK: LOAD BALANCING

Everyone recognizes the frustration of a machine standing still, but not everyone talks about load balancing.

- POWER UNLEASHED: THE 40 KW ADVANTAGE

Extra horsepower doesn’t just sound good on paper; it translates directly into faster throughput.

- EVERY PLATE, A SELLABLE PART

Nothing kills output like re-cuts and grinding. We deliver clean, weld-ready edges that keep parts flowing straight into the next process.

- SAFETY WITHOUT SACRIFICE

Pushing output higher only works if your operators stay safe. We prove you don’t have to choose between the two.

WHY WE USE THE V353 AS REFERENCE

In short, the

machine was built to excel in all five areas, with standout performance in

output and automation. The V353 is a moving-gantry fiber laser plate cutting machine. Cutting takes

place inside a sealed gantry that travels over a buffered stack of plates

resting on a cutting bed that can be extended to 36 m (120 ft). The gantry frame is lightweight yet rigid to support 1.4G acceleration, and it

is fully enclosed for laser safety, even during 45° bevel cutting.

The V353 is also one of the few plate lasers that performs automatic nozzle

changes and in-process quality checks without operator intervention. Together

with the large plate buffer, this enables true lights-out production, including

overnight shifts, which can significantly increase output without adding labor cost.

Hopefully this clarifies my starting position.

One of the V353’s biggest productivity boosters is its long, modular cutting bed, which can be extended up to 36 meters (120 feet).

HIGH-SPEED CUTTING CYCLES

Picture a high power fiber laser racing along at up to 140 m/min (460 ft/min) while the gantry snaps from part to part with 1 G acceleration. Those numbers translate into real-world gains: holes burn through thick plate in seconds, edge quality stays sharp, and the head is on to the next contour before an operator could even reach for the pause button. Faster cycles mean fewer hours per job, which frees capacity for the next order.

ELIMINATING FORKLIFTS

Now think bigger. The V353’s bed can be extended to 36 m (120 ft), so you can stage several full-size 3 × 6 m (10 × 20 ft) sheets at once. With automatic rotation and plate alignment, nestings are adjusted based on how the plate is loaded - squeezing every last component out of each sheet and eliminating the forklift shuffle between jobs. Fewer touches, less scrap and more finished parts flowing downstream.

TRUE 24/7 THROUGHPUT

Finally, hand the night shift to the machine. An automatic nozzle handler with 24 positions, on-table plate measuring, and job buffering let the V353 queue different thicknesses and materials without asking anyone for help. Load up the table at 5 p.m., walk away, and come back to a stack of weld-ready parts the next morning. No overtime, no interruptions, just true 24/7 throughput.

Amazing, right? You get full cutting production overnight, totally automated, without anyone on site.

MORE POWER, MORE OUTPUT

Many people figure that if you double the laser-source power, you automatically double your cutting output. It feels as logical as saying a 400 hp car should go twice as fast as a 200 hp car. In reality, the higher-powered car rockets from 0-100 quicker and delivers more torque, yet both cars usually top out in a similar speed range because aerodynamics, gearing, and tire limits all come into play.

Lasers operate under

the same kinds of physical limits. Beyond a certain point, cut speed is

governed by how fast assist gas can clear the kerf and how well the material

absorbs energy. Those steps take

time, regardless of how many extra kilowatts you throw at them.

That does not mean a

40 kW laser fails to add value; it absolutely boosts throughput. The key is

understanding where the extra power helps.

WHY EQUIP THE VOORTMAN V353 WITH A 40 KW LASER SOURCE?

Choosing the 40 kW option unleashes the V353’s full capability on heavy plate and delivers gains that a 15 kW system simply cannot match in that area:

- Higher

overall output through faster cutting speeds

Thanks to the extra horsepower in a 40 kW laser, the V353 reaches higher feed speeds and makes more effective use of its traverse speed. It reaches cutting speeds a 15 kW machine just cannot touch without risking incomplete penetration or rough edges. On 25 to 50 mm (1 to 2") mild-steel plate, customers routinely see productivity jump by 30 to over 60 percent, depending on assist-gas and nozzle choices. Every second you shave off the cycle puts more finished parts on the table by the end of the shift, so you boost throughput without adding extra hands or overtime.

The weighted average plate thickness of steel fabricators is 12mm. At this thickness even the 15kW laser source of the V353 already cuts 3,5 times faster than the plasma process.

- Wider clean-cut window, right up to 25 mm / 1"

In other words, the 40 kW laser supplies enough energy to keep the entire kerf cross-section molten as it advances through plate up to 25 mm / 1" thick. Maintaining a fully molten kerf is what gives you those smooth, oxide-free edges that need little or no secondary finishing. - Faster feed rates, less thermal load on the machine

Because the beam can travel quicker, it dwells for a shorter time on any single spot. That lowers heat transfer into the slats and supporting structure, extending the life of the cutting bed and reducing maintenance downtime. - Broader fiber core, easier part extraction

A 40 kW source uses a thicker delivery fiber, which yields a slightly wider kerf. While that trims a few seconds off raw cutting speed, it pays back by making skeleton break-up and part removal noticeably easier - especially on nested 50 mm parts - so downstream handling stays efficient.

The Voortman V353 comes with a powerful and efficient 40 kW fiber laser, so it cuts through 50 mm (2 inch) thick plates with ease and without compromising on quality.

IN SHORT

The 40 kW configuration cuts thicker plate better and faster, protects the V353’s mechanics, and smooths the entire removal and handling workflow. The result is higher sustainable throughput and lower total cost per part in heavy-gauge production.

EVERY PLATE A SELLABLE PART

You load a 3 × 6 m (10 × 20 ft) sheet, press start, and the V353’s 15 kW or 40 kW fiber laser, guided by its vision-driven nozzle changer, traces every profile in a single pass - bevels included - even through 50 mm (2 in) plate. Cut product edges come off the table clean and within spec, so parts are weld ready. Operators skip grinding, re-cuts, and manual touch-ups, and components flow straight into welding and assembly while the V353 is already cutting your next nest.

Fewer interruptions, less scrap, and consistent accuracy combine to free capacity, letting the same crew push more tonnes and tons of steel through the shop each shift without adding labor or overtime.

Did you know? Products can be produced using common cut, because of the great perpendicularity of both cutting sides, improving output.

SAFETY AND OUTPUT WORKING HAND IN HAND

When the day shift starts, the V353’s long table is already full of freshly cut parts, thanks to its overnight, unmanned run. Your first job is to clear those parts and slide in new stock plates with the next nests queued up. While the laser is busy cutting the new sheets, you keep clearing the remaining pieces and try to stay ahead of the machine.

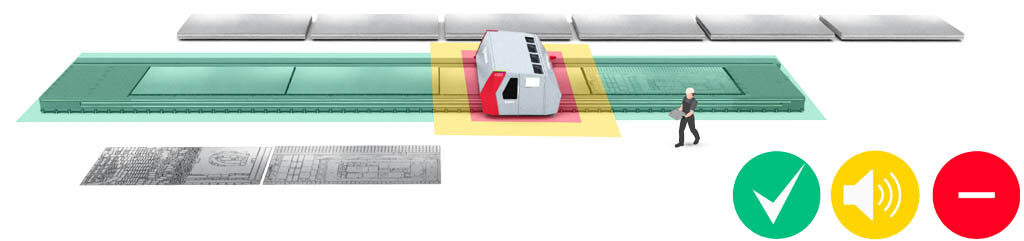

With a gantry that can cross a 3 × 6 m (10 × 20 ft) plate in about

two seconds, operator safety is essential. Multi-zone laser scanners guard the

work area by creating an outer warning band and an inner hard-stop zone. If

anything breaks the stop zone, the beam shuts off and the gantry parks

instantly; once the path is clear, VACAM resets automatically and cutting

resumes almost without pause.

The built-in Resume Cutting feature then guides you right back to the exact pierce point, using live cutting data so the contour finishes cleanly with no witness mark. Fewer safety lockouts, quicker job changeovers, and continuous cutting time add up to a smoother shift and more parts out the door.

STAY UP-TO-DATE

Join now so these updates land in your inbox, not your rear-view mirror.

Each edition brings you straight-to-the-point tips, real shop-floor insights, and advance notice of our next four deep dives.