V807

ALL-IN-ONE ROBOTIC CUTTING ON A COMPACT FOOTPRINT

The Voortman V807 delivers complete profile cutting in one pass with unmatched automation, precision, and minimal operator input. Process profiles from 10 x 50 mm up to 460 x 1,140 mm (H x W) and handle materials up to 15 tons.

- Combines cutting, coping, drilling, milling, marking and free form processing

- Four sides processing allows to process square and rectangular tubes

- Unmanned production and no manual production

- Only 10-day installation setup, indoors & outdoors

- Precisely cut and ready to assemble products

Compatible with software solutions:

LogicSteel CADCAM | LogicSteel PRODUCTIVITY

OVERVIEW

The Voortman V807 delivers all-in-one automated profile processing fully compliant with international standards such as EN 1090, ISO 9013 and AISC. By combining precise robotic plasma cutting with intelligent material handling, it eliminates manual programming, parameter setting and part handling. Compared to traditional sawing and milling, the V807 offers faster, more flexible processing with consistent, high-quality results from raw profile to finished product.

MACHINES IN THIS PRODUCT LINE

SUCCESS STORIES

We deeply value our customers and their feedback; it's what drives us to keep improving and innovating. Curious how our machines make a difference? Hear directly from our customers as they share their experiences.

APPLICATIONS

FEATURES

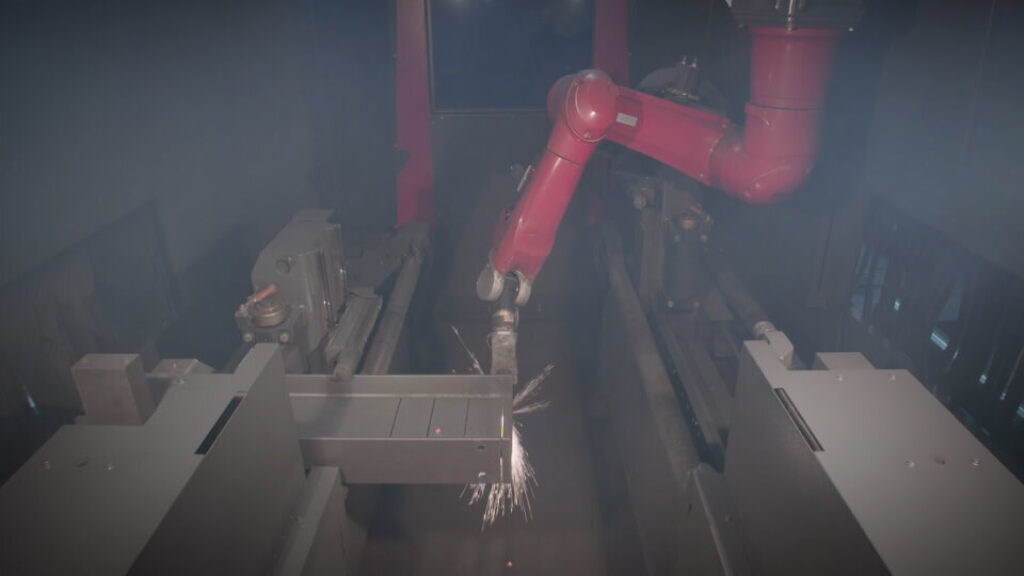

FULL ACCESS WITH 7-AXIS CUTTING

A 6-axis robot combined with a 360° rotatable W-axis cuts and marks all four profile sides without repositioning . Complete complex shapes in one automated setup.

HIGH-SPEED HANDLING FOR LARGE PROFILES

Processes profiles of unlimited length and up to 15,000 kg with roller conveyors moving at 60 m/min, ensuring nonstop, efficient throughput.

INTELLIGENT AUTOMATION FOR PERFECT RESULTS

Real-time angle adjustment, collision prediction, and automatic TCP calibration deliver precise cuts, protect consumables, and guarantee flawless alignment without manual intervention.

BENEFITS

INTEGRATED MEASURING ROLLER SYSTEM

The integrated measuring roller system positions profiles precisely without tape, markers, or complex layouts, reducing errors and saving time.

SPACE SAVING DESIGN

Compact footprint and integrated extraction keep your facility clean, organized, and safe while freeing up valuable floor space.

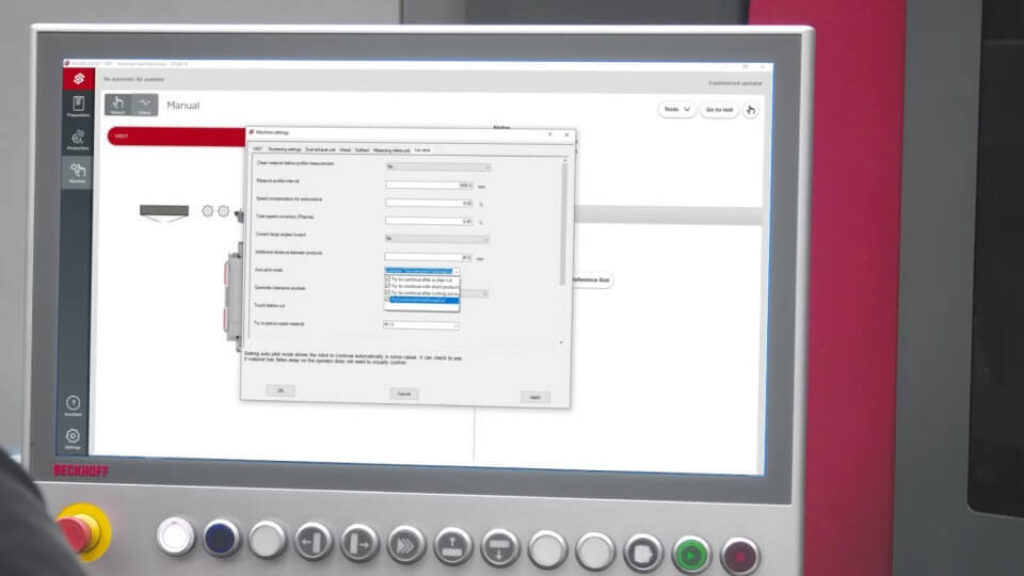

AUTOPILOT MODE

Automatic inspection and adjustment after each cut eliminate manual intervention, ensuring uninterrupted workflow and maximum productivity.

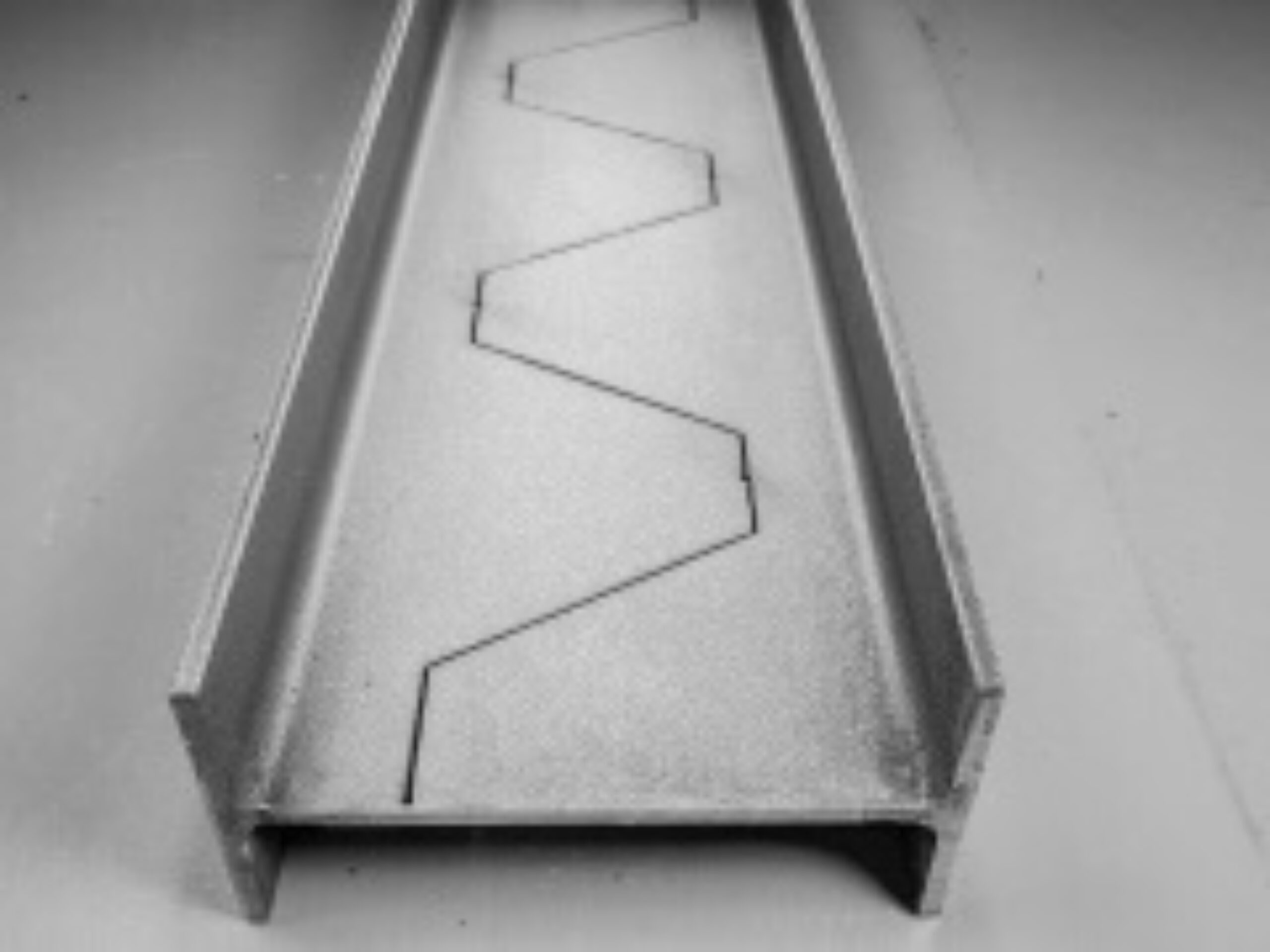

COMMON CUT NESTING

By sharing cut lines between parts, the system reduces material waste, shortens cutting time, and simplifies downstream processing.

STITCHING / COMBINED OUTFEED

Connected parts exit as one stable assembly, making unloading and sorting safer and more efficient.

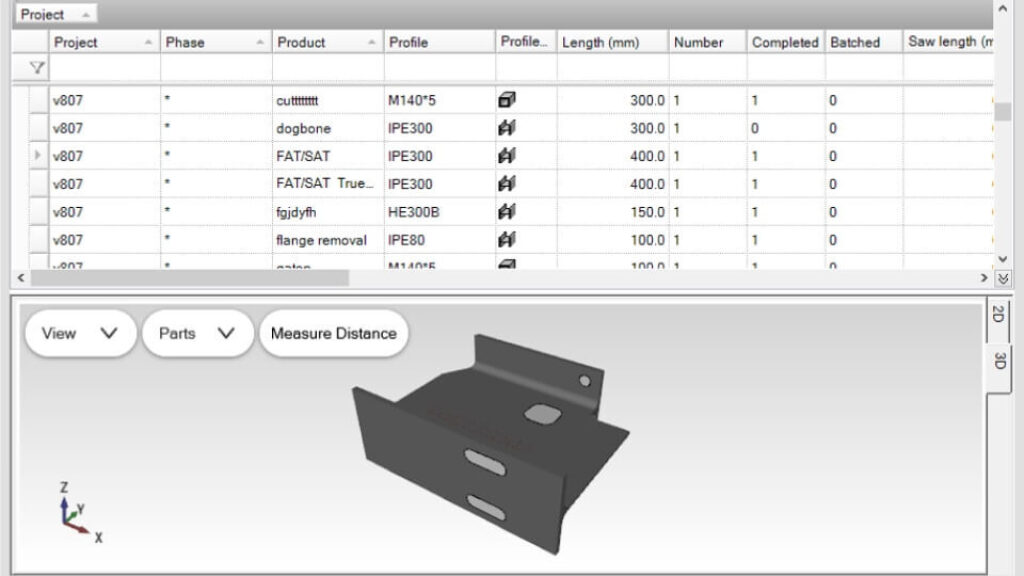

AUTOMATIC 3D IMPORT

Predefined cutting logic and file-based automation remove manual programming, enabling quick, error-free work preparation even for non-experts.

SMART PARAMETER SELECTION

The machine automatically chooses cutting parameters and consumables for each profile, guaranteeing consistent quality and eliminating rework.

PIERCE-ON-WASTE

Piercing on scrap instead of the main profile protects cutting edges, reduces wear, and lowers maintenance costs.

SPECIFICATIONS

UPGRADE YOUR MACHINE

Roller Conveyors & Cross Transporters

Enhance logistics with extra roller conveyors or cross-transfer units to expand buffers or link downstream machines.

Upgrade to MSI

Prepare the V807 for future MSI automation. This ensures layout, conveyors, and VACAM control are ready for seamless integration with Voortman equipment like drilling, sawing, or blasting, without major changes or downtime.

LogicSteel Software Suite

Voortman’s cloud-based suite connects CAD-to-CAM, factory planning, real-time tracking, and XR quality checks. LogicSteel gives full visibility, actionable data, and tighter control over steel operations.

Oxy-fuel Cutting

Add an oxyfuel torch for thicker materials and geometries plasma can’t reach, such as web cuts near flanges. Expand your cutting range for maximum flexibility.

Round Pipe Cutting

Adapt the machine for pipe cutting with extra supports, rotation sensors, and software.

Smart Castellation

Boost cutting speed up to 20% with synchronized robot and profile movement. No re-measuring or re-clamping, enabling unlimited lengths and smoother cuts with fewer burn marks.

CorePlus Hypertherm

Switch from Core to CorePlus gas console to use argon for cleaner, sharper marking and improved piercing up to 10% thicker mild steel at 170A and 300A.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

Yes. The Voortman V807 meets EN 1090, ISO 9013 Class 3, and AISC thermal cutting standards, delivering certification-ready holes without secondary processing. Hypertherm True Hole technology improves roundness and edge quality, especially on small diameters, reducing rework.

The Voortman V807 maintains ±1 mm accuracy for bolt-ready results straight off the machine. Real-time calibration and robotic precision ensure parts fit correctly without grinding or manual correction.

The Voortman V807 is delivered with the robotic cutting module with Staubli robot, Hypertherm XPR300 plasma source, Voortman control software, automatic measuring system, collision detection, extraction units, and safety enclosure. Installation, training, commissioning, and online support are also provided.

The Voortman V807 is built for continuous industrial use and achieves over 95% uptime in multi-shift environments. Its robotic arm has no wear parts, and smart diagnostics prevent interruptions.

The Voortman V807 features automatic lubrication, self-calibrating sensors, and easy service access. Remote diagnostics allow fast troubleshooting without on-site visits. Global service hubs and preventive maintenance packages ensure maximum uptime.

No. Import the DSTV file, select the profile, and press start. The machine automatically executes all operations, making it easy for even inexperienced users.

Yes. The Voortman V807 connects seamlessly with other Voortman machines and conveyors. Automated handling and VACAM software enable coordinated workflow and optimized throughput.