VACAM

Unrivaled and proven most user friendly CNC controller

Streamline your fabrication process with DIGI-SUPPLY, from sales order to delivery with precise costing, seamless work preparation, and enhanced production control. Our advanced planning module offers real-time insights and efficient scheduling.

ㅤ

En savoir plus

User Friendly

Interface

After an operator learns how to use VACAM on one machine, they’ll easily be able to operate another Voortman machine since all use the same user-friendly software. The VACAM PLC variable monitor includes a touchscreen and robust buttons.

Manual

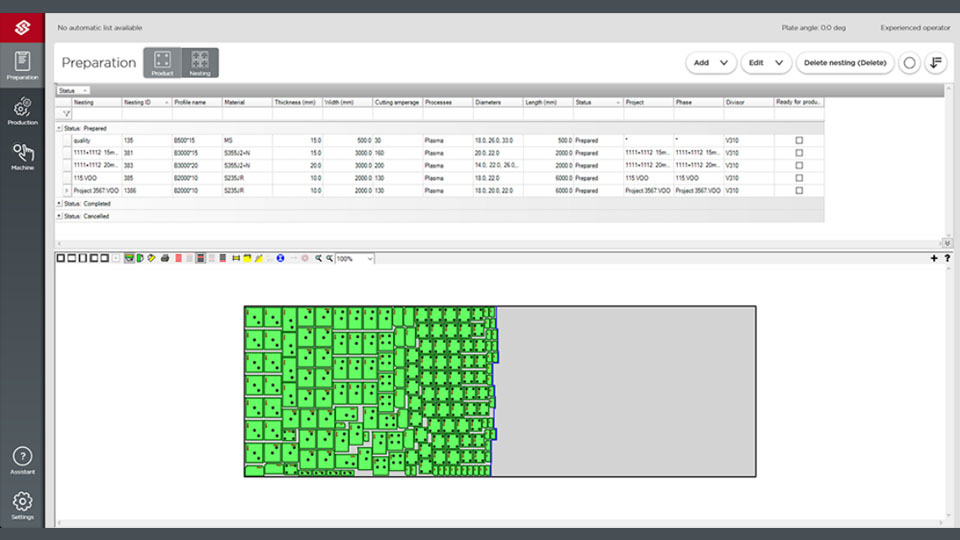

Nesting

Software updates boost automation, cutting manual labor costs. Operations and material transport can be optimized without major design changes, thanks to software updates. Voortman’s internal control allows for quick, tested updates, benefiting customers throughout the machinery’s lifespan.

Complete

Integration

The software and hardware are developed together, maximizing the benefits of their combined engineering efforts. Voortman’s in-house expertise allows us to preemptively address any issues, ensuring optimal performance. VACAM is continuously improved based on customer feedback.

MACHINES

The Voortman plate machines come out of the box with VACAM, ensuring efficient and automated workflows. Select one of the machines below to learn more about the possibilities.

VACAM + OFFICE

Expand VACAM from the workfloor to your office. Send production data to the machinery in the factory from your office. You can check if producing what you need is possible prior to sending it to your machines in your system for production. Profile nestings can easily be exchanged between MRP software and VACAM using the industry-standard DSTV+ file format, no matter which third-party MRP software you use (StruMIS, ConstruSteel, Tekla Powerfab, and more). With VACAM Office, production information is available throughout the entire company.

SUPPORTED FILE FORMATS

DSTV Files

DSTV+ Files

NC Files

FEATURES

Manual Part

Creation

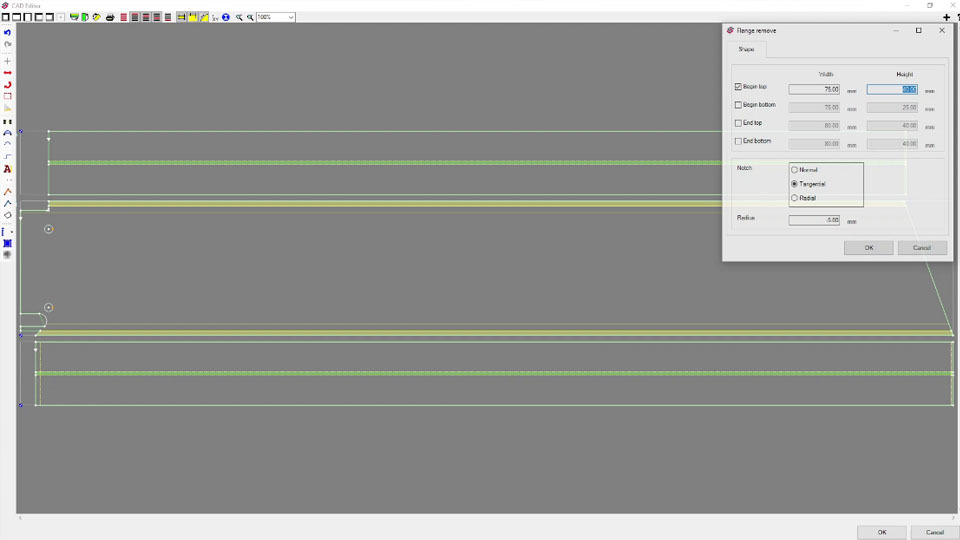

VACAM allows you to prepare and send production data to factory machinery from your office. You can verify production feasibility before sending data to your machines. It also allows the operator to manually create parts when needed directly on the machine.

Manual

Nesting

Profile nestings can easily be exchanged between MRP software and VACAM using the industry-standard DSTV+ file format, no matter which third-party MRP software you use (StruMIS, ConstruSteel, Tekla Powerfab, etc.).

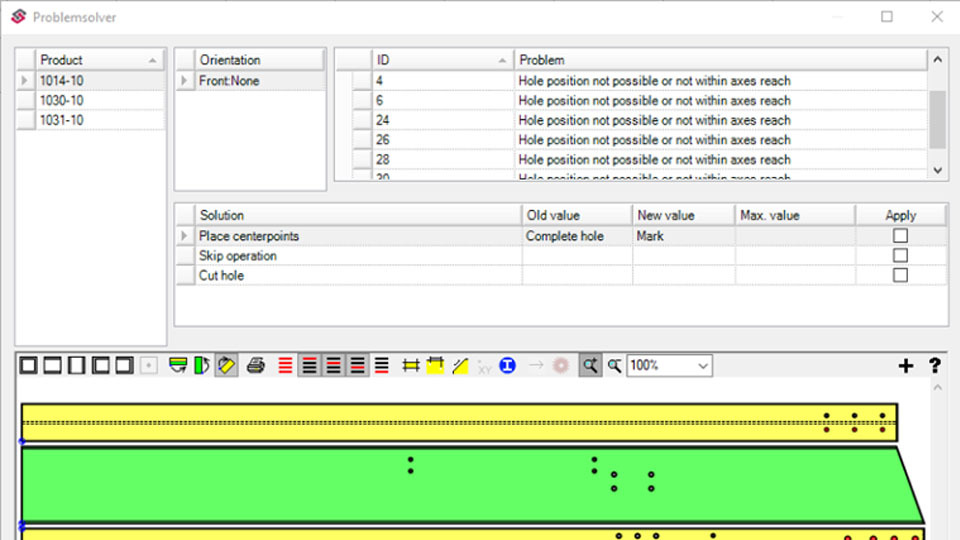

VACAM Problem

Solver

VACAM includes a Problem solver. Whenever VACAM foresees production problems, it will suggest the best solutions. These checks ensure that the product can be manufactured efficiently and effectively without requiring manual intervention, specialized experience, or extensive knowledge from the operator.

INTERESTED OR

HAVING QUESTIONS?

We understand software

Our sales and service team can answer any of your questions or help you to make the right decisions.

ㅤ