Geautomatiseerde plaatbewerking opnieuw gedefinieerd!

Maak kennis met de Voortman V320, uw toegang tot geavanceerde, ononderbroken plaatbewerking - een machine die altijd doorgaat. De V320 is ontworpen voor topefficiëntie en transformeert uw productieproces met continue geautomatiseerde workflows, met een robuuste, snelle klaptafel, een brede transportband en automatische spaanafvoer.

Lees meerWE WETEN DAT HET VEEL IS

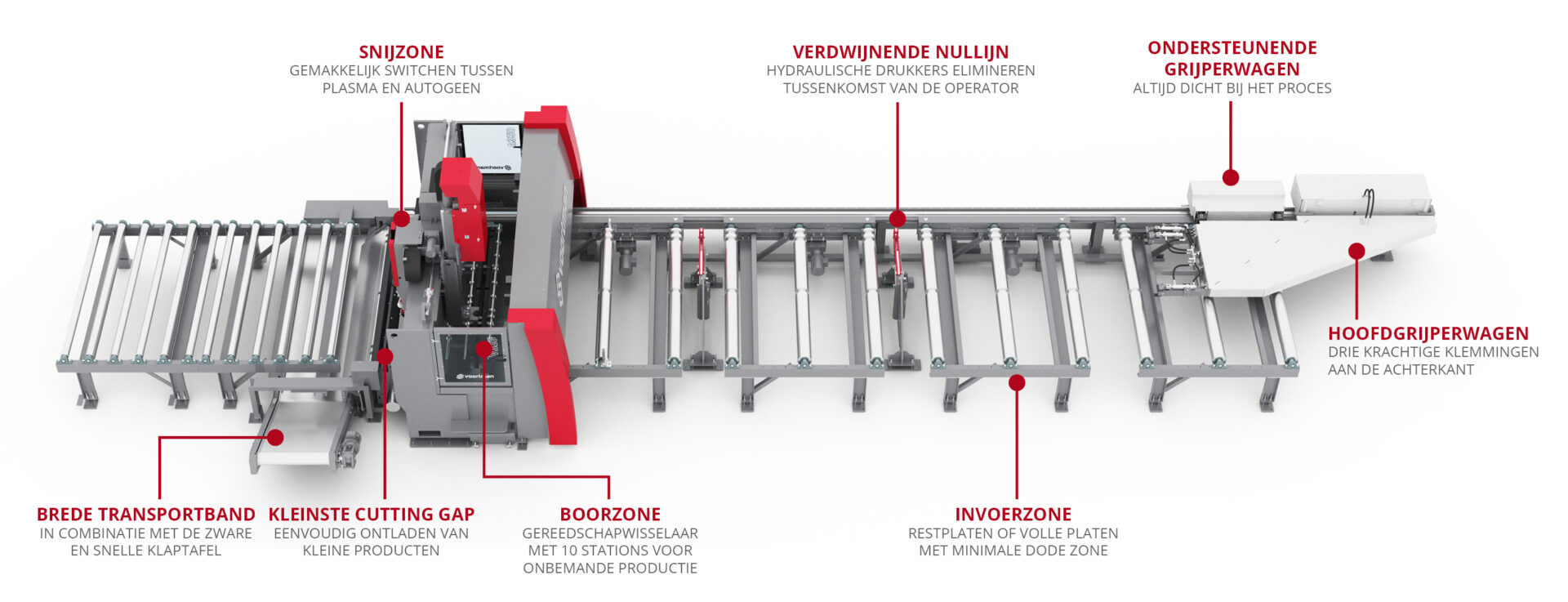

DIT IS DE VOORTMAN V320 IN EEN NOTENDOP

Ben Morrall geeft u een beknopt overzicht van de unieke kenmerken van de V320. Volg hem rechtstreeks vanaf de productievloer van GB Structures, waar de V320 zijn bijzondere eigenschappen bewijst en hun activiteiten transformeert.

PRODUCTIVITEIT MAXIMALISEREN

EN MANUELE INTERVENTIE MINIMALISEREN

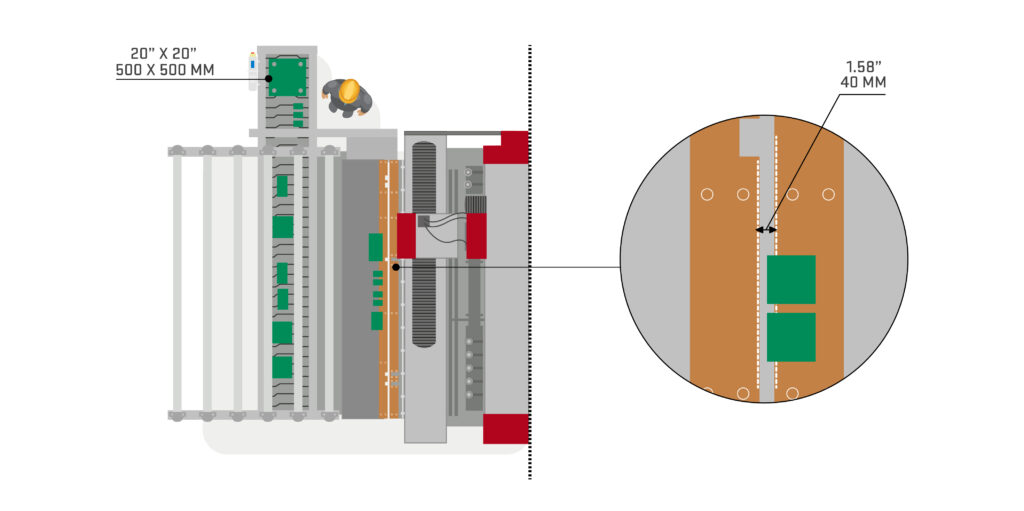

De machine ontlaadt autonoom onderdelen tot 500 x 500 mm, met een gewicht tot 75 kg, waardoor manuele interventie gedurende langere perioden tot een minimum wordt beperkt. Operators kunnen zich concentreren op andere belangrijke taken en komen alleen terug voor specifieke handmatige taken of om de onderdelen te sorteren die automatisch in de onderdelenbak vallen. Het innovatieve grijpersysteem van de V320 minimaliseert de dode zone, waardoor u extreem dicht bij de grijpers kunt snijden en de materiaalopbrengst maximaliseert.

VERLAAG UW KOSTEN PER ONDERDEEL

GEREDUCEERDE DODE ZONE

De V320 zorgt voor een efficiënter materiaalgebruik en verwerkt volledige platen, zelfs de ruimtes tussen de grijperwagenklemmen. Dankzij een slim ontwerp kan de zijgrijperwagen zich losmaken van de plaat tijdens de laatste bewerkingsfase, wat de opbrengst van het materiaal optimaliseert.

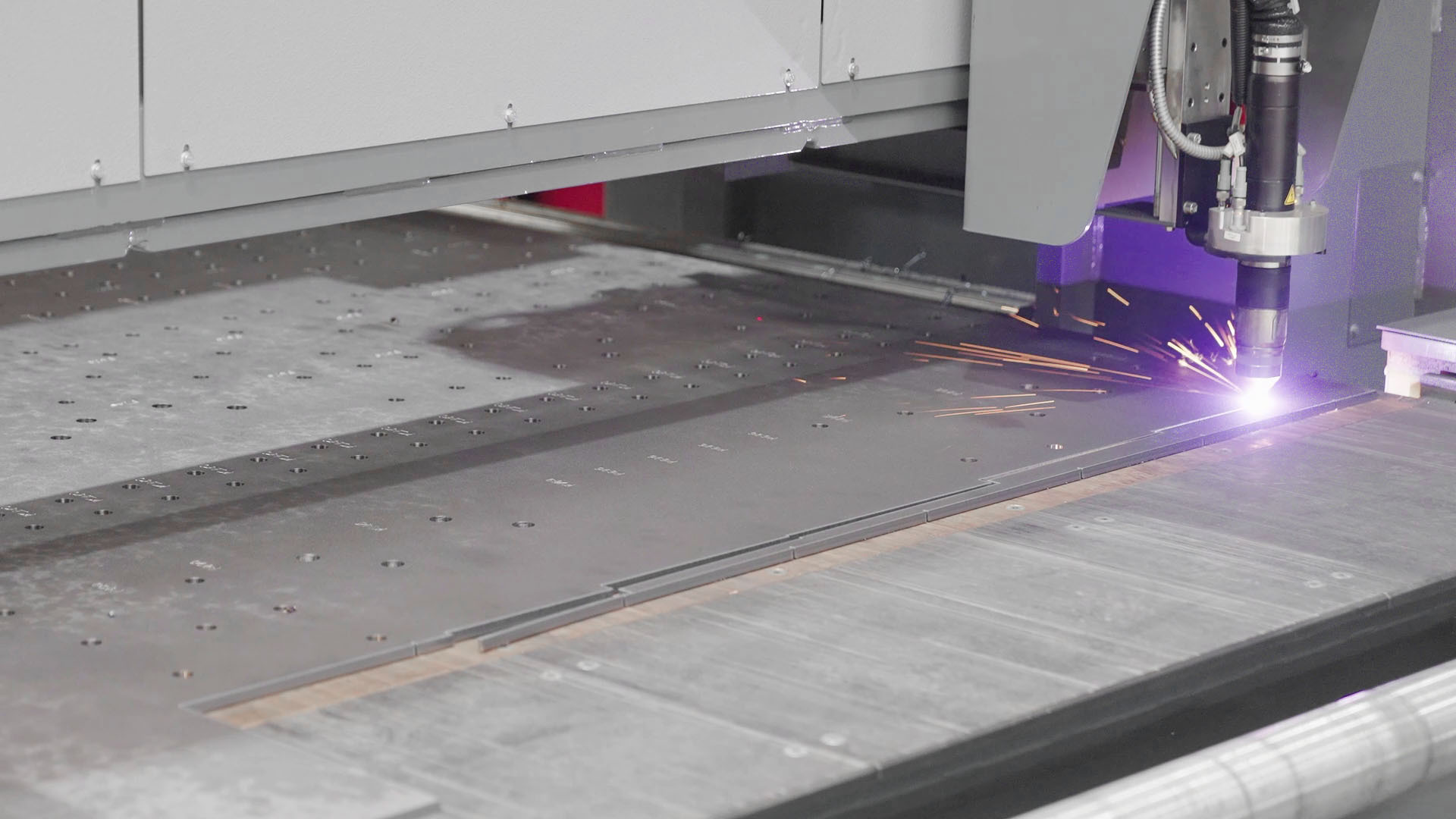

MINIMALE AFVAL

Deze machine excelleert in het minimaliseren van materiaalverspilling en operationele kosten dankzij efficiënte nesting op restplaten en HD Multidrop. Het optimaliseert het gebruik van bijna de gehele plaatoppervlakte, waardoor de efficiëntie aanzienlijk wordt verhoogd.

BRUGSNIJDEN

Ervaar verbeterde efficiëntie met geneste brugsnedes! Deze aanpak leidt tot een besparing van wel 8 seconden per product, omdat het mogelijk maakt een hele rij producten tegelijkertijd te ontladen. Dit vermindert de tijd dat de plasmaboog inactief is en verlaagt het aantal benodigde starts. Het gevolg? Minder verbruikskosten per onderdeel en een optimaler gebruik van materialen.

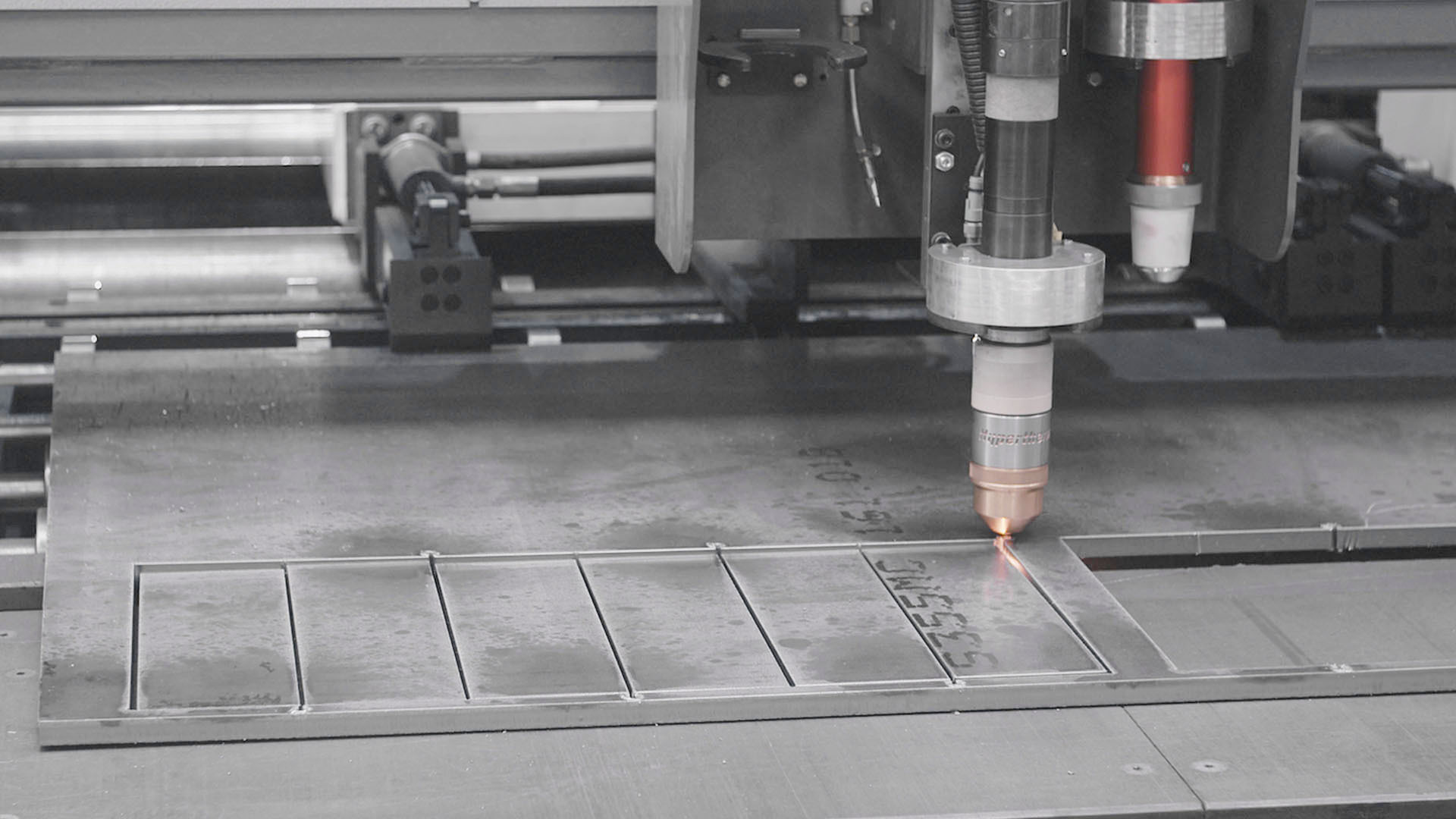

PROFITEER VAN DE VOORDELEN VAN HD MULTIDROP

MINDER AFVAL - MEER EFFICIËNTIE

HD Multidrop zorgt ervoor dat bijna de hele oppervlakte van de plaat optimaal wordt benut, waardoor minder afval ontstaat. De innovatieve methode biedt deze 3 belangrijkste voordelen:

1. MATERIAALOPBRENGST MAXIMALISEREN

Een geavanceerde nestingtechniek verbetert de materiaalopbrengst en efficiëntie bij het snijden van platen aanzienlijk. Dit levert kostenbesparingen en een milieuvriendelijkere bewerking op.

2. MINDER KRAANGEBRUIK EN MANUELE HANDELING

Aangezien het hele frame volledig wordt gebruikt, verbetert onze workflow de veiligheid aanzienlijk door de risico's te beperken die vaak gepaard gaan met zwaar tillen en handmatig materiaal hanteren.

3. MINDER SLIJTAGE VAN CONSUMABLES, GAS- EN STROOMVERBRUIK

HD Multidrop verlaagt de bedrijfskosten door het aantal snijmeters te verlagen en zo de slijtage van consumables en het stroom- en gasverbruik te verminderen. Dit leidt tot minder consumable wissels, lagere onderhoudskosten en een duurzamere bewerking.

ONBEMAND POTENTIEEL BENUTTEN DANKZIJ GEAVANCEERDE AUTOMATISERING

Ontdek de ultieme automatiseringservaring met onze V320, speciaal ontworpen voor langdurige onbemande productieprocessen. Als marktleider in efficiëntie biedt de V320 een naadloze geautomatiseerde workflow, verrijkt met geavanceerde functies zoals een robuuste, snelwerkende klaptafel, en brede transportband, automatische spaanafvoer en nog veel meer. Het resultaat? Minimale manuele tussenkomst, maximale productiviteit in onbemande situaties. Ontdek hieronder meer.

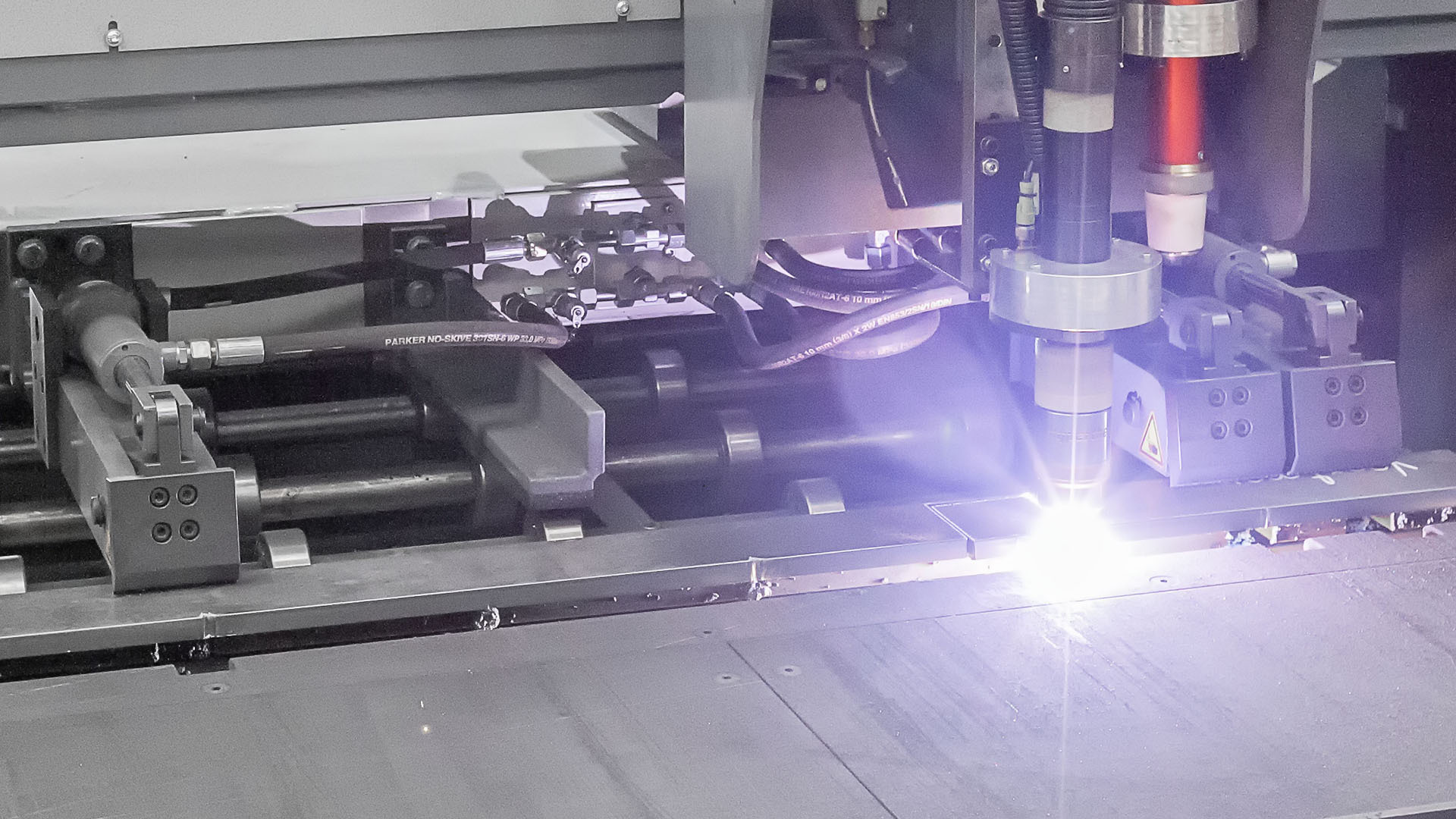

KLEINSTE OPENING, GROTE EFFICIËNTIE

MOEITELOZE AFVOER VAN KLEINE PRODUCTEN

Vergeet het tijdrovende proces van veel kleine producten uit de slakbak halen en geniet van lange perioden onbemand werken. Dankzij de uitzonderlijk kleine cutting gap, worden zelfs producten van 70 x 70 mm door de zware klaptafel op de transportband gelost.

ALLEEN DAAR ZIJN WANNEER NODIG

Het Voortman Operator Dashboard toont de tijd per bewerking, het aantal bewerkingen dat nog moet worden uitgevoerd en de resterende productietijd. Maar het belangrijkste; het laat zien wanneer een operator bij de machine aanwezig moet zijn voor een manuele actie. Op momenten dat er geen operators bij de machine nodig zijn, kan er op andere plekken in uw werkomgeving gewerkt worden. Met andere woorden: waarde toevoegen waar dat op dat moment het meest nodig is.

DE HOOGSTE PRODUCTIVITEIT BEHALEN

Maximaliseer uw productiecapaciteit met de geavanceerde technologieën van Voortman op de V320. Ons magnetisch montagesysteem zorgt voor een snelle omsteltijd en minimale stilstand, terwijl de snelste hoogteregeling de snede-tot-snede tijd drastisch verkorten. De Voortman Resume Cutting functionaliteit zorgt voor een snelle, hoogwaardige herstart wanneer dat nodig is, en onze toonaangevende klaptafel versnelt de bewerking, waardoor de algehele productiviteit aanzienlijk toeneemt.

KWALITEIT EN UPTIME VOOROP

De V320 is ontworpen om uit te blinken in kwaliteit en uptime. Elk onderdeel en elke functie is zorgvuldig ontworpen om aan deze belangrijke doelstelling te voldoen. Met name onze softwareoplossingen stellen u in staat om geavanceerde snedes uit te voeren met een verhoogde efficiëntie, en dat alles met behoud of verbetering van de productkwaliteit.

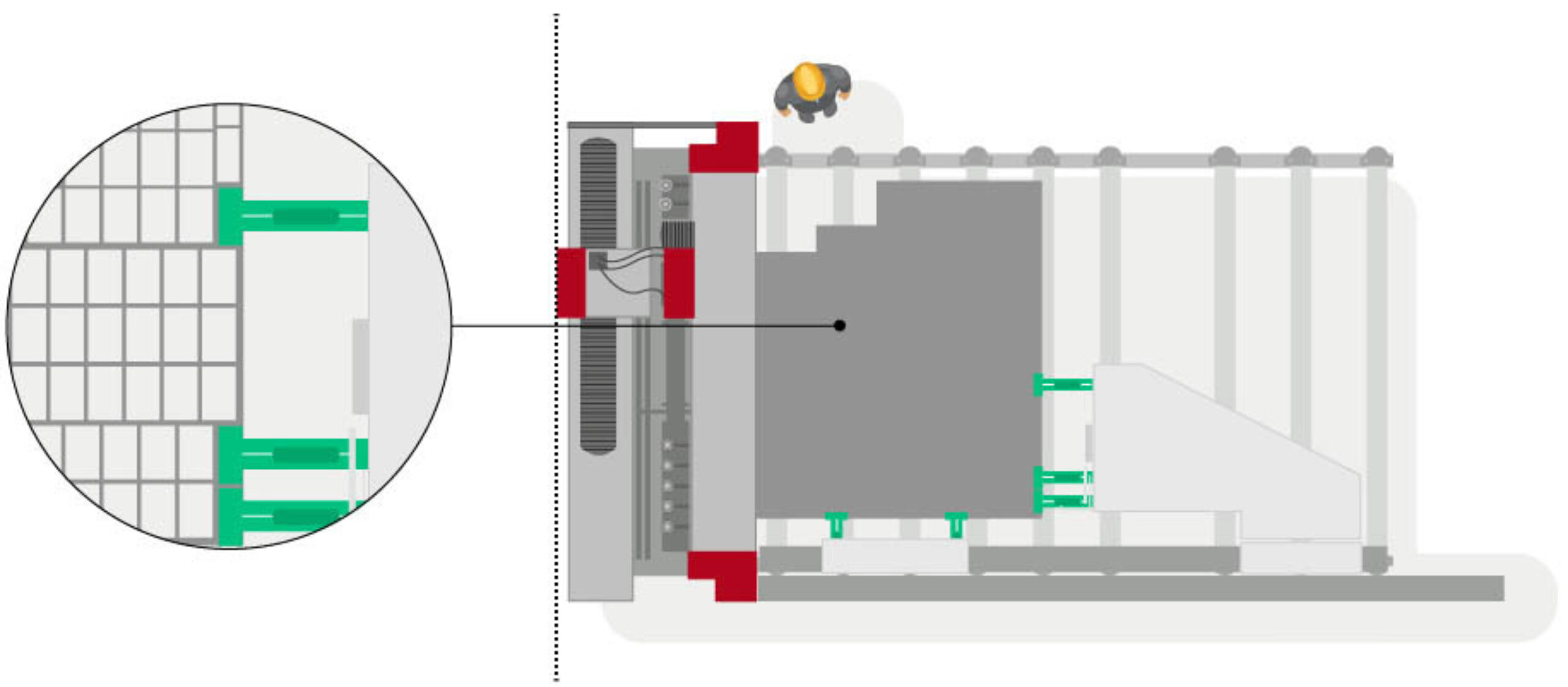

DUBBELE GRIJPERWAGENS

PRECIEZE PLAATBEWEGING VOOR HOOGWAARDIGE RESULTATEN

Het innovatieve grijpersysteem van de V320 minimaliseert de dode zone, waardoor u uiterst dicht bij de grijpers kunt snijden om zo de materiaalopbrengst te maximaliseren. De V320 heeft twee grijperwagens voor nauwkeurige plaatbewegingen. De hoofdgrijperwagen, uitgerust met drie klemmen, houdt het achterste deel van de plaat vast, terwijl de ondersteunende grijperwagen, met twee klemmen de plaat langs de nullijn houdt. Dit dubbele grijpersysteem zorgt voor een nauwkeurige bewerking van volledige platen en strippen, en draagt zo bij aan de verhoging van de kwaliteit van uw eindproducten.

MATERIAALOPBRENGST MAXIMALISEREN EN CONSUMABLE KOSTEN VERLAGEN

De V320 onderscheidt zich in het efficiënt gebruiken van materialen en kostenbesparingen. Dankzij het innovatieve ontwerp wordt de dode zone geminimaliseerd, waardoor de materiaalopbrengst wordt gemaximaliseerd. De geïntegreerde VACAM-Software helpt bij het optimale beheer van consumables, waarbij kosten en kwaliteit in balans zijn. Verrijkt met functies zoals efficiënt nesting in restplaten en HD Multidrop, slaagt de V320 erin zowel materiaalverspilling als operationele kosten drastisch te reduceren.

WEBINAR / Voortman & Hypertherm

HOE UW PLASMA CONSUMABLE MANAGEMENT TE VERBETEREN

Het kiezen van het juiste moment voor het verwisselen van verbruiksmaterialen is cruciaal, nietwaar? Tijdens ons webinar met Hypertherm hebben we uiteenlopende aspecten besproken om het beheer van plasma-verbruiksmaterialen te verbeteren. Onze experts deelden bruikbare inzichten en slimme strategieën die u onmiddellijk kunt toepassen in uw dagelijkse werkzaamheden. Bereid u voor om uw plasma consumables management naar een hoger niveau te tillen met de opname van onze webinar!

INZICHT KRIJGEN IN BEZETTINGSGRAAD EN PERIODEN VAN STILSTAND

"Wat is de huidige bezettingsgraad van mijn machines en wat draagt bij aan eventuele stilstand?"

Goede vraag! Vertrouwen op de ervaring van operators en managers kan voldoende zijn voor dagelijkse werkzaamheden, maar voor efficiëntieverbeteringen is inzicht in de werkelijke machinestatus en de redenen voor stilstand cruciaal.

Vertrouw op LogicSteel PRODUCTIVITY om:

Inzichten te krijgen in uw machineproductie output en geschiedenis.

Gemakkelijk vast te stellen waarom er downtime was.

- Uw machine uptime te verhogen.

Specificaties

| Voortman V320 | ||

|---|---|---|

| Voortman V320 | ||

| Werkbreedte | ft | 6 or 10 |

| Werklengte | ft | 20, 30 or 40 |

| Maximale snijdikte | inch | 3 |

| Gewicht positionering | lbs | 16,500 or 19,850 |

| Boren en positioneren | Servo motors | |

| Positioneersnelheid X | f/min | 65-1/2 |

| Positioneersnelheid Y | f/min | 98-1/2 |

| Positioneersnelheid Z | f/min | 98-1/2 |

| Markeren | milling/plasma | |

| Boorunits | vertical | 1 |

| Nominaal vermogen | Hp | 40 |

| Boorkop met snelheid | rpm (stepless) | 0 - 2,500 |

| Gereedschapswisselaar | 2 x 5 | |

| Boorhouder | SK40 | |

| Boordiameter | inch | 13/64 - 1-9/16 |

| Draadtappen | M6 - M30 | |

| Plasma | up to (amp) | 400 |

| Autogeen toorts | 1 | |