Fiber laser cutting - how it lowers your cost per product

BY STEF ROHAAN, PRODUCT MANAGER, VOORTMAN

For most people, fiber laser technology is a whole new way of processing thicker steel plates. And it brings some serious advantages to the table. Of course, it’s well known for boosting output (we dive into that in our article (How fiber laser plate cutting boosts your production output), but that’s only part of the story. This same technology also helps lower your cost per product in a big way.

In this article,

we’ll show you how all those benefits add up - helping you make more parts, spend

less time, and get more value from every plate you process.

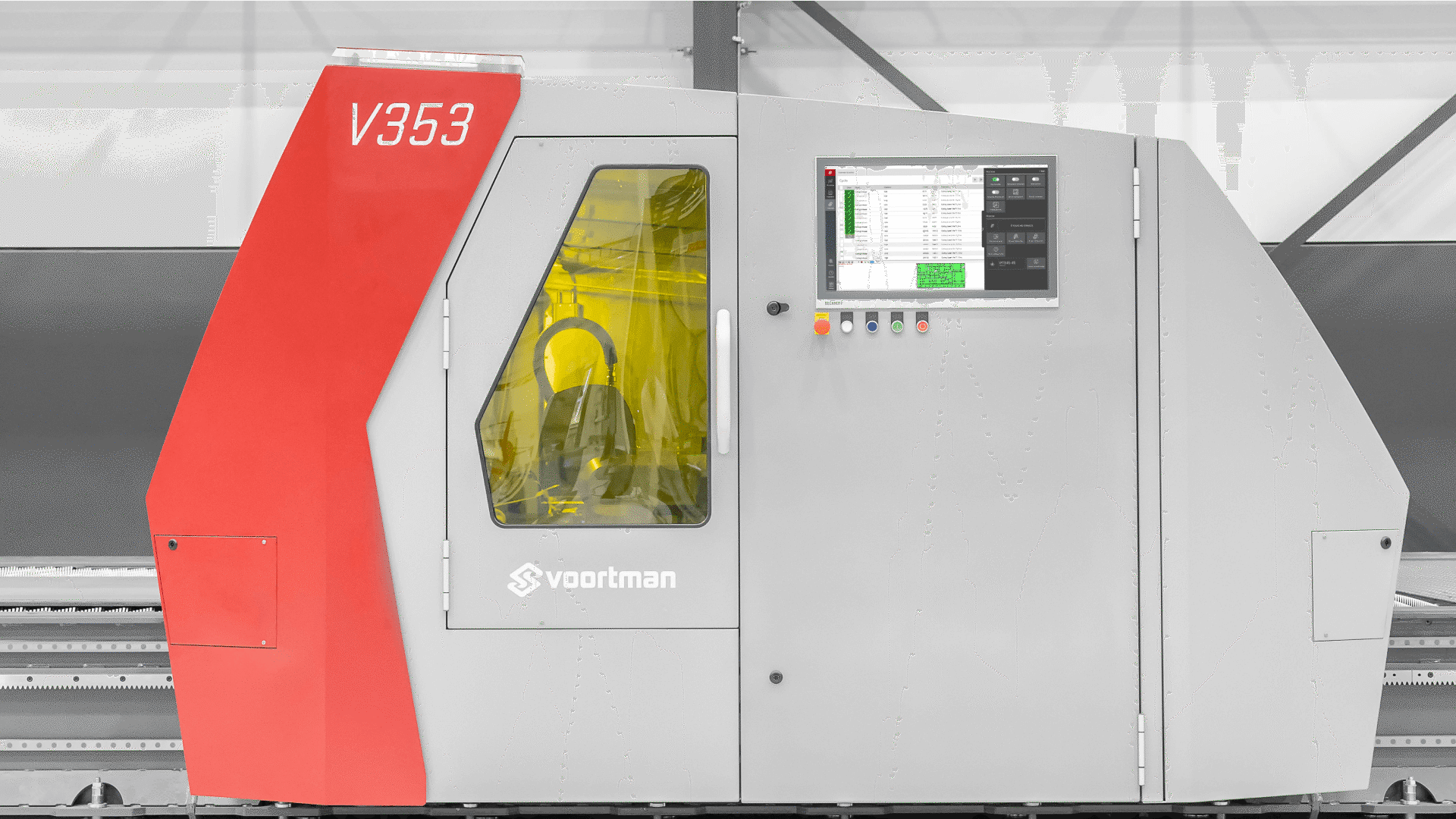

The Voortman V353 is a great example of how modern laser cutting can completely

transform your production process. Designed for high precision, automation, and

efficiency, it shows just how much more you can get out of every hour and every

plate. There are several reasons why this machine delivers a faster return on investment, each contributing in its own way to lowering costs.

To make it easy, we’ve divided the main benefits into four key topics:

- UNMANNED OVERNIGHT CUTTING WITH FIBER LASER

No extra people, no compromise on quality. Sounds impossible? Not anymore.

- MAINTENANCE STAYS SIMPLE AND DOWNTIME STAYS SHORT

Cut holes in seconds, skip the drilling, and watch your costs drop. One consumable does it all.

- LARGE-FORMAT NESTING EFFICIENCY

Cut more, waste less. The large-format Voortman V353 makes every plate count - FEWER MOVEMENTS, LOWER COSTS

Weld-ready parts straight off the table. Less handling, faster flow, and lower costs with every cut.

UNMANNED OVERNIGHT CUTTING WITH FIBER LASER - WAIT, WHAT?

Yes, correct. Cutting steel plates overnight, completely unmanned, is not just a possibility anymore - it’s a practical, proven strategy to lower your cost per product. Whether you run one shift or two, the Voortman V353 turns idle shop hours into productive output - without hiring extra people or compromising on quality.

Let’s walk through how it works and what it means for your bottom line.

Can you imagine? One day shift turning into 1,000+ extra cutting hours and 3,000 more tonnes a year - all with the same crew!

HOW LASER ENABLES OVERNIGHT CUTTING

In traditional

cutting, two main factors have always prevented unmanned operation: fire risk

and inconsistent quality. Open flames and reactive gases create obvious safety

concerns, but the bigger challenge is the number of variables that constantly

affect cut quality. Gas pressure fluctuations, consumable wear, and material inconsistencies all affect the final result, and controlling these factors requires a skilled and experienced operator.

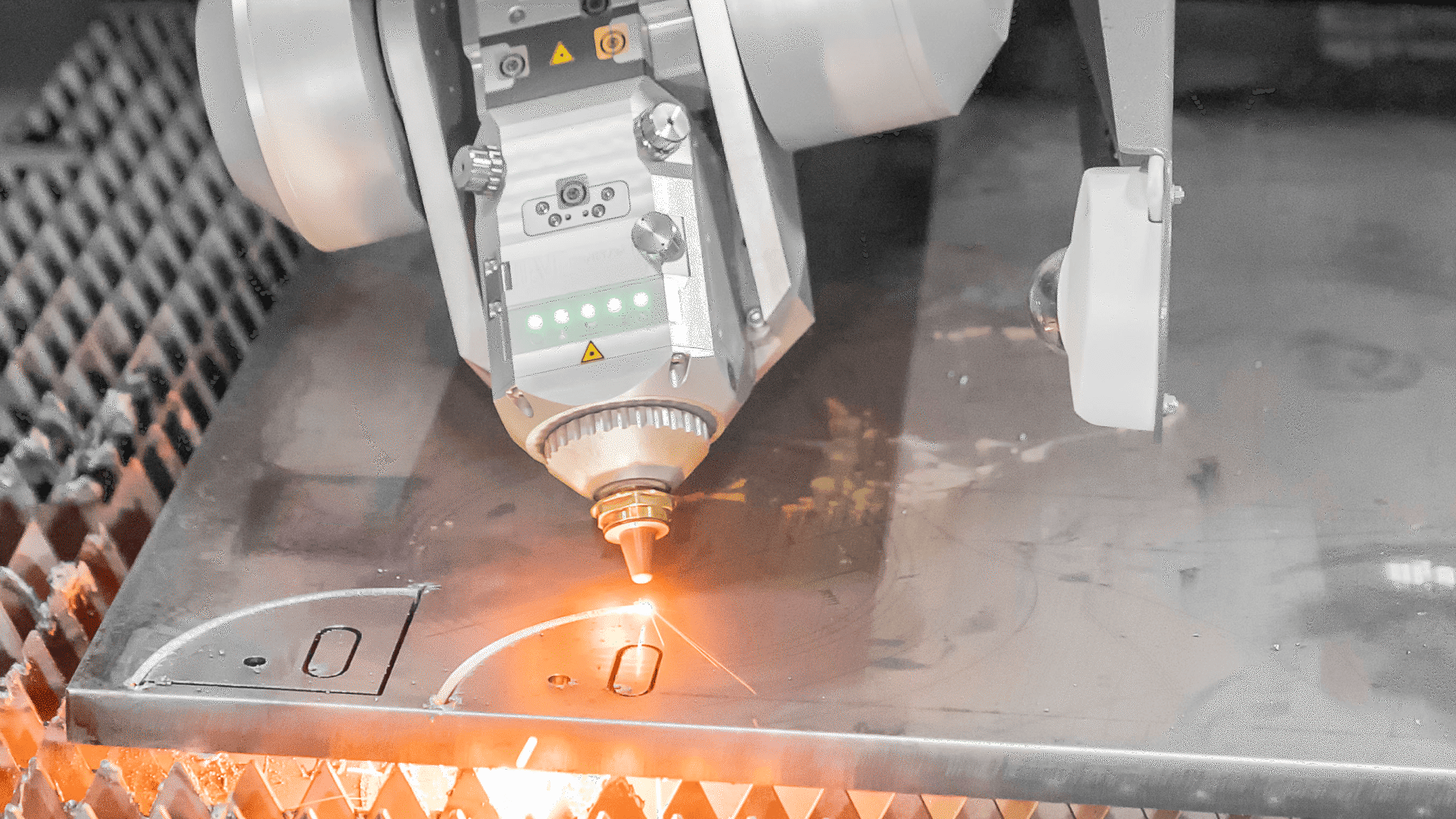

Laser cutting changes that picture completely. It’s a solid-state, flame-free

process that only uses support gases and produces a stable, highly focused

beam with a very small heat-affected zone. That makes it both safe and

predictable- ideal for running overnight without supervision.

The

Voortman V353 takes this to a new level. The process runs inside a fully enclosed cutting cabinet, where pneumatic

valves open only in the active cutting zone to remove

sparks and dust. At the same time, the system minimizes process variation with

only a single consumable (the nozzle) which is automatically cleaned, inspected, and replaced by the 24-slot nozzle handler.

Its built-in vision control continuously checks roundness and alignment to guarantee consistent

quality.

The process runs inside a fully enclosed cutting cabinet, where pneumatic valves open only in the active cutting zone to remove sparks and dust.

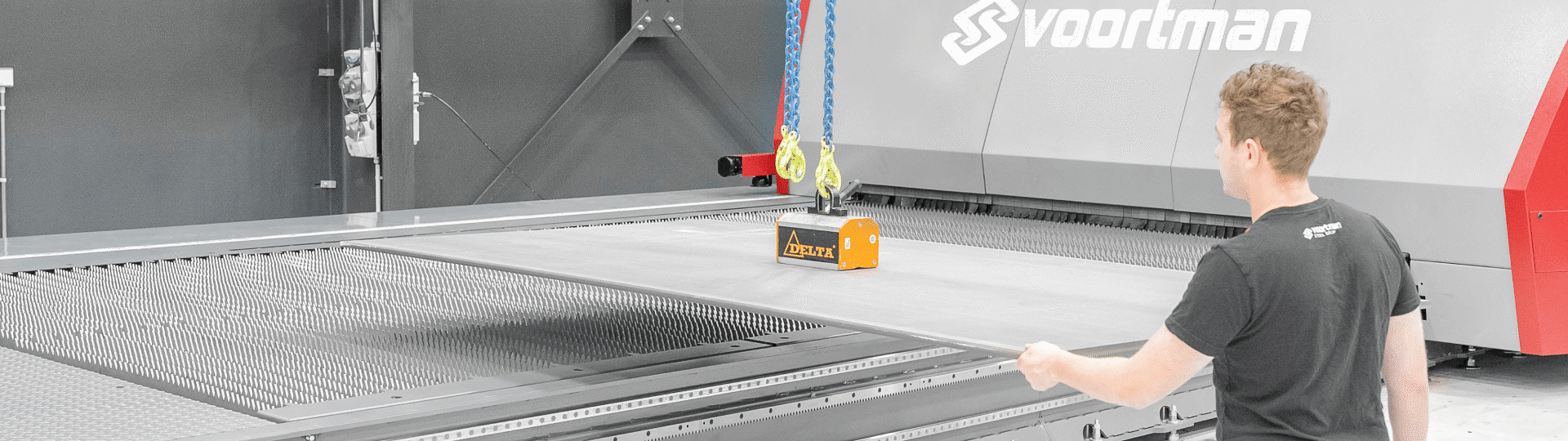

PREPARE FOR AN UNMANNED NIGHT

The modular cutting bed of the V353 is designed for long, continuous production. With Plate Buffering, you can load several plates across the 3m (10 ft) wide bed, and the machine will process them one after another without stopping, perfect for unmanned operation. Before leaving at the end of the shift, simply have your operator fill the bed, ideally with thicker plates. These longer-running jobs make the best use of overnight hours. By the time the morning crew arrives, the parts are finished and ready to unload, while the V353 seamlessly continues cutting from the next buffered position. It’s a straightforward way to turn downtime into valuable production time.

Operators are hard to find, consistency even harder

Let's not forget (skilled) operators are scarce, and rotating or temporary staff can introduce quality drift across shifts. For many companies, night and weekend shifts are hard to staff or not feasible at all. Unmanned laser production captures value in hours that would otherwise sit idle. The V353’s combination of buffer, automation, and safety systems is built to exploit those unstaffed windows.

WHAT’S IN IT FOR ME?

Let’s put it into perspective. Say you’re running a single day shift and processing around 12,000 tonnes of steel a year. That’s already a busy schedule, with roughly 1,425 effective production hours out of a possible 1,900. But after that day shift ends, your machine sits still for half the week. With the Voortman V353, you can turn those idle nights and weekends into productive time -adding another 1,000 to 1,300 cutting hours a year without hiring anyone new.

In real terms, that’s about 3,000 extra tonnes of steel processed just by letting the V353 keep working while everyone’s home. Your labor costs stay the same, because the machine runs fully unmanned, yet your output climbs by as much as 25 to 30 percent. For most one-shift operations, that means €30,000 to €40,000 in labor savings every year, plus the added value of more parts delivered on time. Same crew, same floor space, just a lot more productivity.

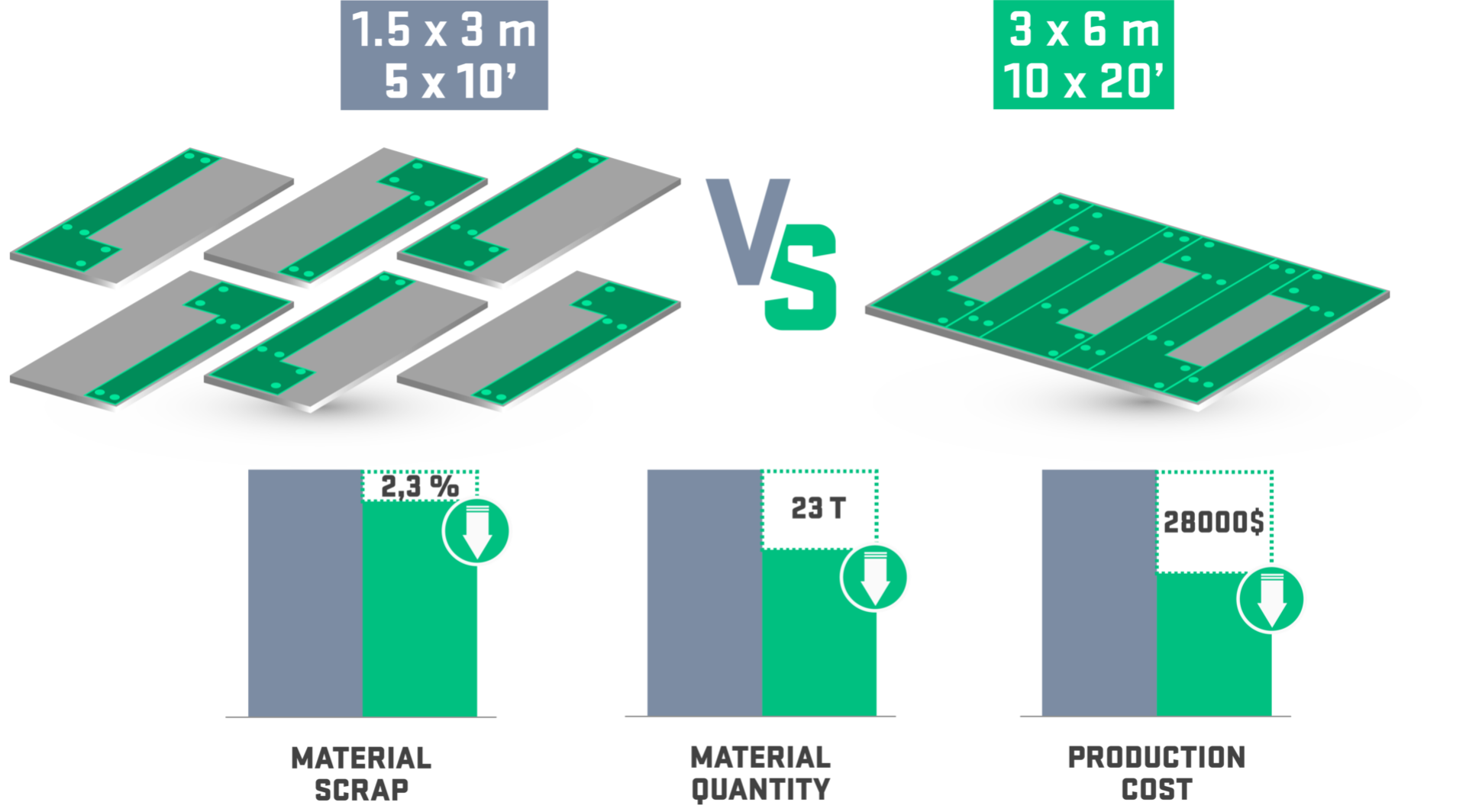

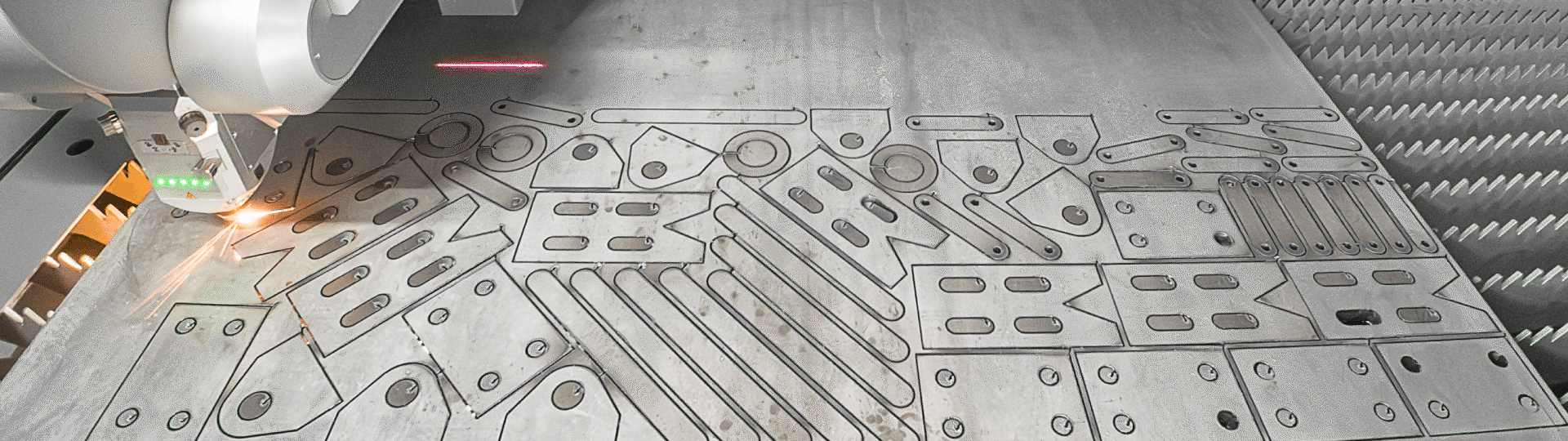

LARGE-FORMAT NESTING LETS YOU CUT THE SCRAP

When it comes to plate processing, size truly matters. A larger cutting bed doesn’t just let you handle bigger sheets - it lets you use them far more efficiently. The Voortman V353, with its large-format cutting bed for plates up to 3 × 6 meters (10 × 20 ft), is designed to make every square inch of steel count.

By

nesting parts on a large plate instead of multiple smaller ones, you gain the

freedom to position components closer together, rotate them for a tighter fit,

and combine jobs with different thicknesses or priorities. This large-format nesting minimizes unused areas

between parts, so more of each plate becomes usable product instead of scrap.

The result is higher material yield, fewer remnants, and lower handling and

storage costs.

And these savings aren’t just nice on paper. They’re real and measurable. Switching from a small-format laser (1.5 × 3 m) to a large-format laser (3 × 6 m) cuts material scrap by around 2.3 percent. In practical terms, that’s roughly 23 tons of steel saved every year for a machine processing about 1,000 tons per shift, worth around €3,450 in recovered scrap value. Compared to a large-format plasma cutter, the difference grows even bigger. About 33 tons of steel saved per year, or roughly €4,950 in value. Add it all up, and a fully utilized large-format laser like the V353 can save more than €28,000 a year in material alone. That’s money that stays in your pocket instead of going into the scrap bin.

ALSO REDUCE WASTE AT THE CUTTING LEVEL

The

precision of the V353’s fiber laser cutting head takes this efficiency even further. With its fine

kerf width, short lead-ins, no lead-outs, and the

ability to common cut shared edges

between parts, the machine reduces waste at the cutting level too. Each small

optimization adds up to substantial material savings over time, especially when

you’re processing heavy plate day after day.

Supporting

it all is Voortman’s advanced software, which automatically calculates the most efficient layout for each

job. It can queue multiple plates, nest parts from different orders together,

and keep improving efficiency with every run.

IN SHORT

The impact is easy to measure. Fewer offcuts mean less scrap to manage, fewer plate changes, and more parts per ton of steel purchased. In other words, large-format nesting doesn’t just save material, it saves money, pushing your cost per part lower and your productivity higher.

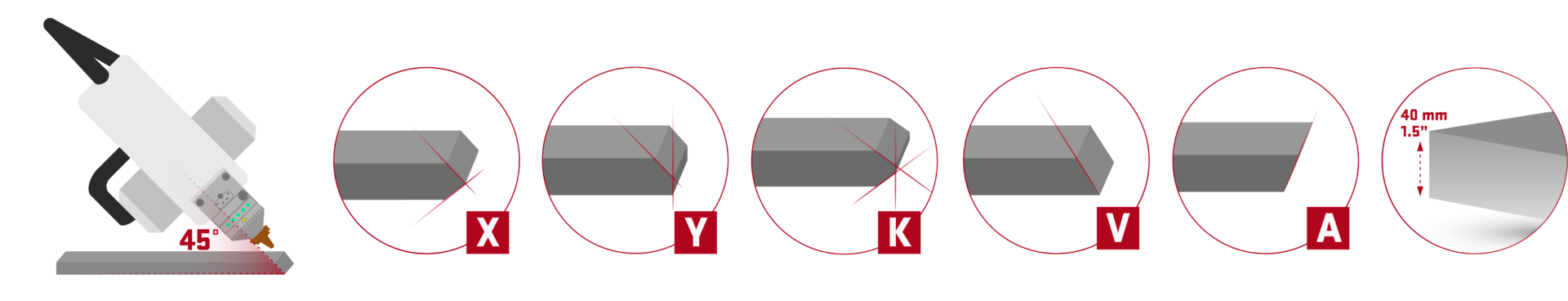

FEWER MOVEMENTS, LOWER COSTS

Every minute spent prepping edges or moving parts between stations adds hidden cost to your production. Each time a plate or finished part has to be moved to another machine or a welding prep area, you’re paying in handling time, forklift movement, and lost workflow efficiency.

The Voortman V353 helps minimize those extra steps. Its cutting capability means plates come off the table weld-ready, with smooth, oxide-free edges. Whether you’re cutting A-, V-, X-, K-, or Y-bevels up to 45°, the V353 delivers consistent, repeatable results straight from the cut. Parts flow to welding or assembly with minimal detours through prep stations. Both the 20 kW and 40 kW models maintain this quality within a wide clean-cut window up to 25 mm (1 in) thick (40kW), keeping throughput high and floor traffic low.

Fewer movements, fewer touches, and faster flow. All of it adds up to less waste and a lower cost per part from start to finish.

Fewer movements, fewer touches, and faster flow. All of it adds up to less waste and a lower cost per part from start to finish.

STAY UP-TO-DATE

Join now so these updates land in your inbox, not your rear-view mirror.

Each edition brings you straight-to-the-point tips, real shop-floor insights, and advance notice of our next four deep dives.