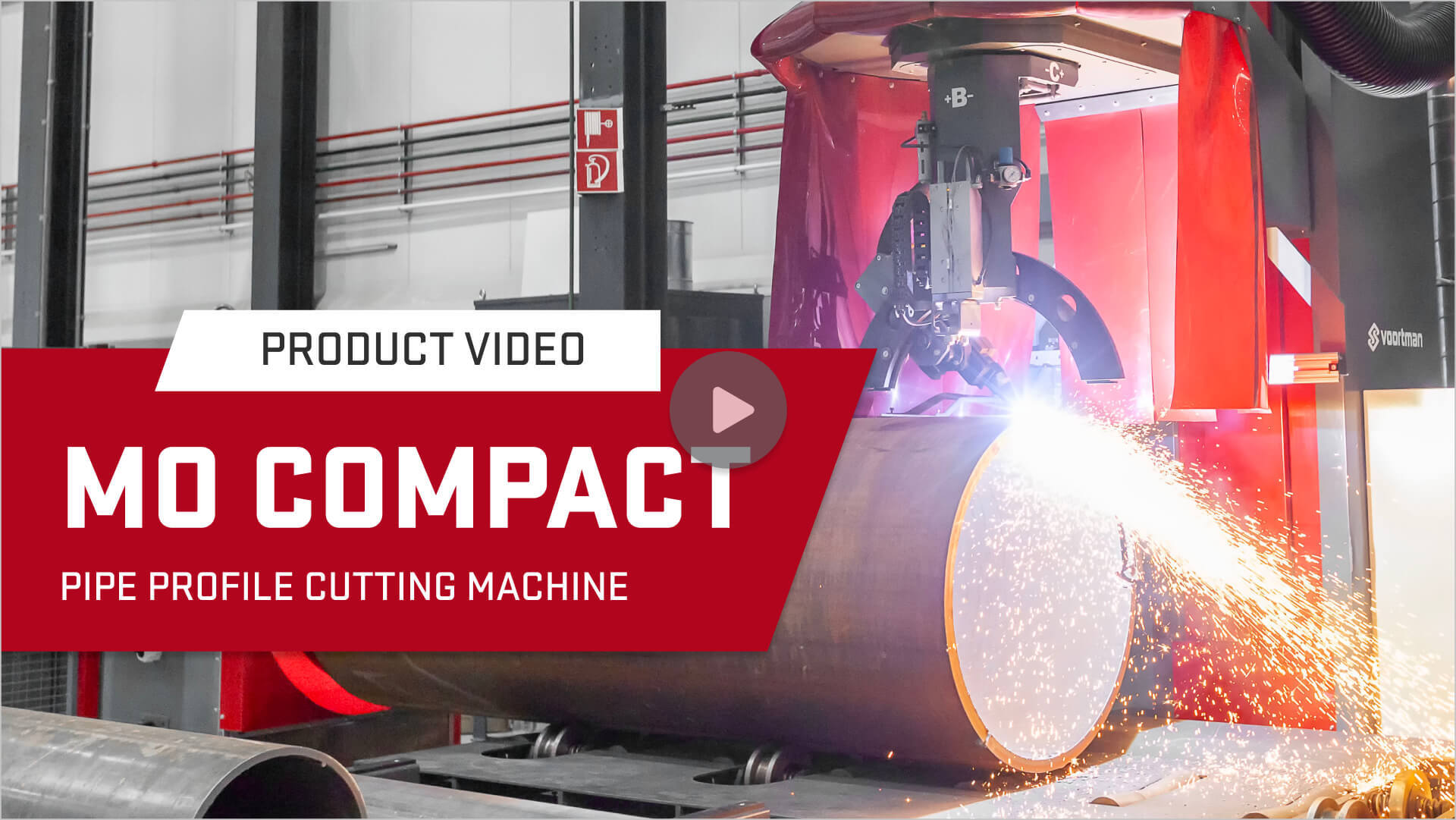

MO COMPACT

PIPE PROFILE CUTTING MACHINE

Precision and efficiency in a compact design, perfect for small to medium-sized pipe profile cutting with advanced logistical systems.

- 6 CNC Axis for high precision and clean cuts

- Designed for easy operation

- Smallest footprint among comparable machines

Compatible with software solutions:

Corobs | PypeServer

OVERVIEW

The Voortman MO Compact is engineered for industries that demand high precision and efficiency in pipe cutting. It’s equipped with advanced logistical systems that streamline tube handling, boosting productivity and ease of use. Ideal for manufacturers working with small to medium-sized pipes, the MO Compact excels in applications where flexibility, accuracy, and repeatability are critical; making it especially valuable in sectors like mechanical contracting, shipbuilding, and construction, where precise pipe profiles are essential for reliable assembly and structural integrity.

MACHINES IN THIS PRODUCT LINE

SUCCESS STORIES

We deeply value our customers and their feedback; it's what drives us to keep improving and innovating. Curious how our machines make a difference? Hear directly from our customers as they share their experiences.

APPLICATIONS

FEATURES

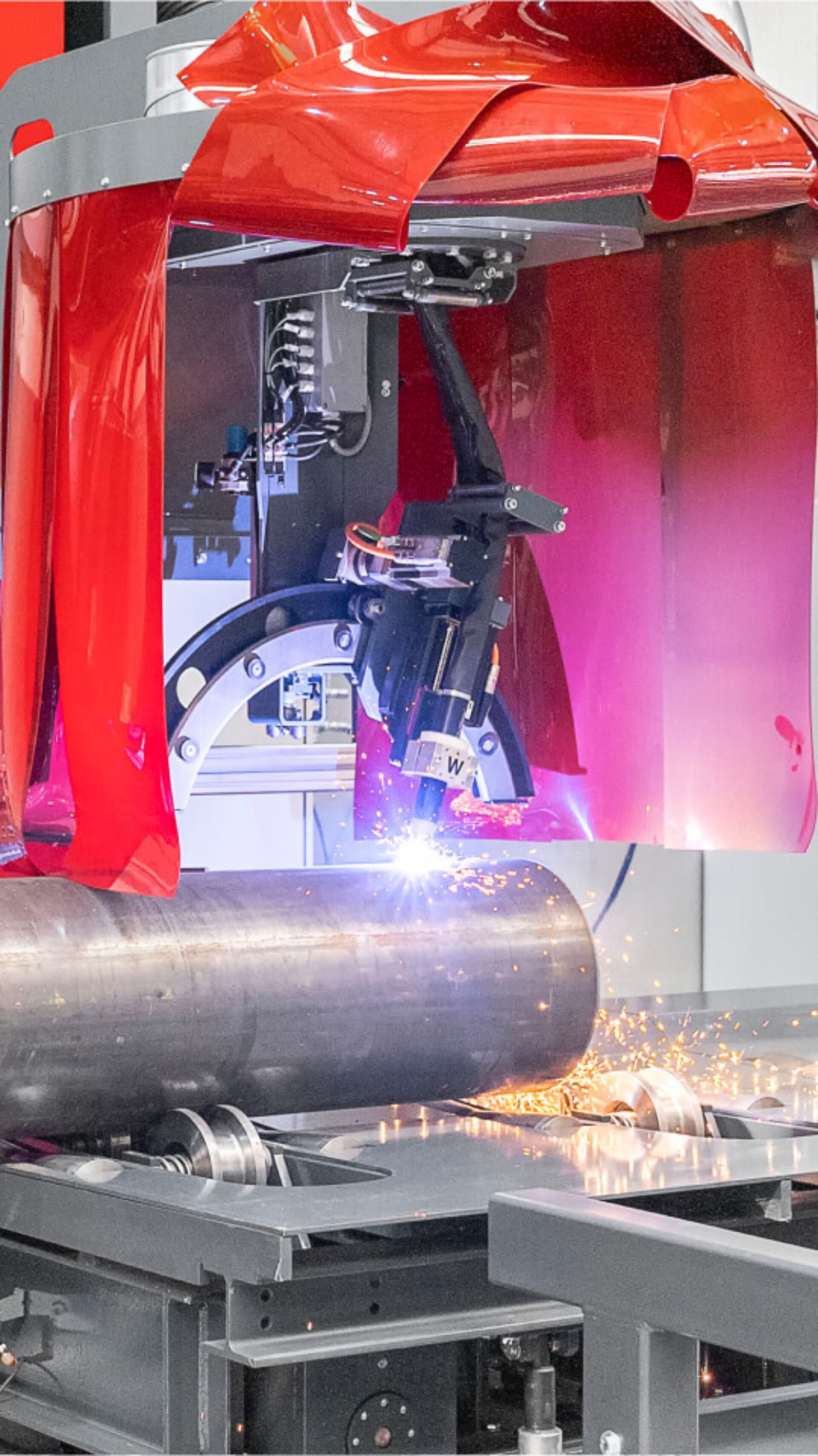

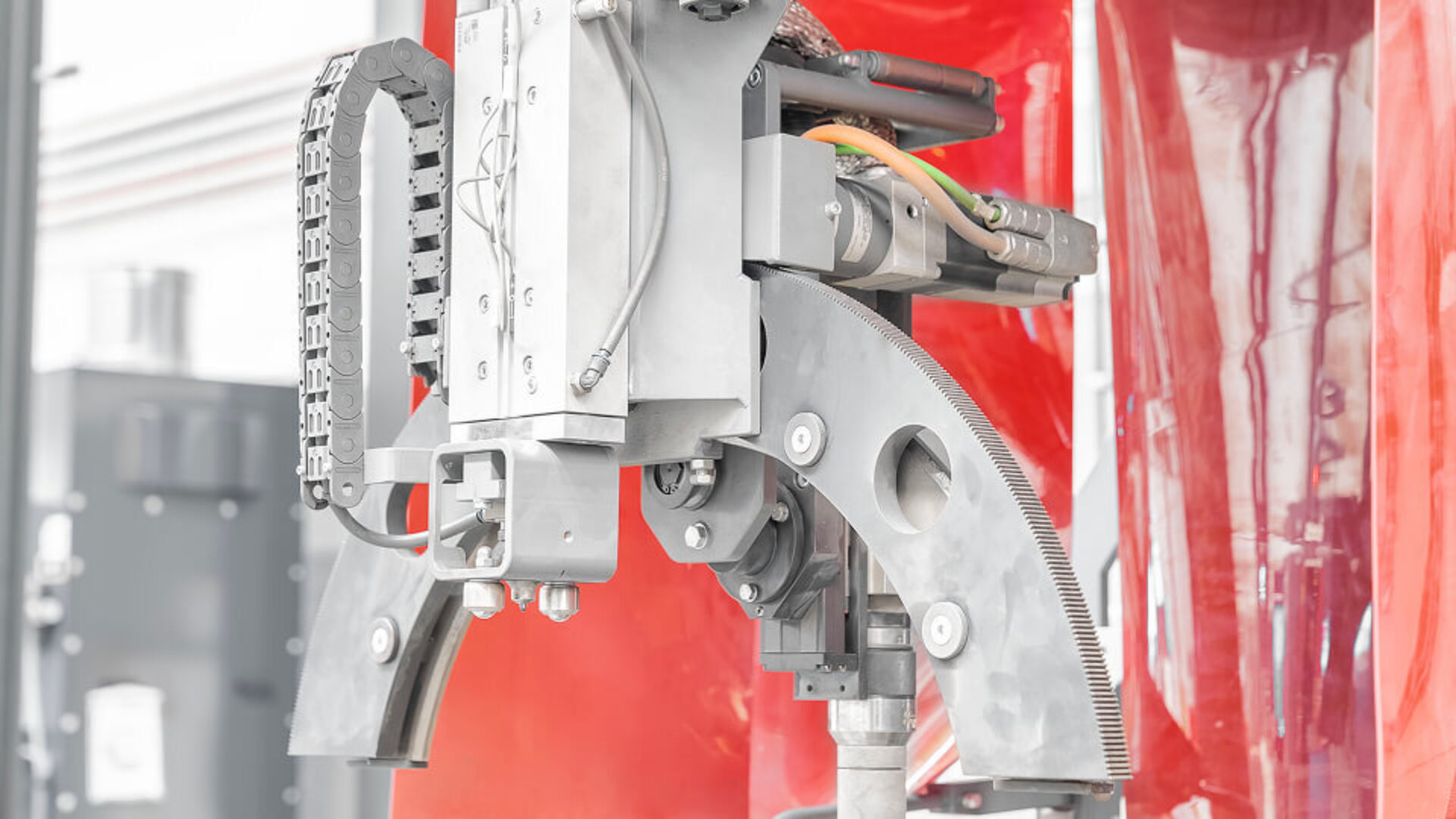

6 CNC AXES WITH W-AXIS RETRACTION

Delivers precise, clean cuts, even around welding seams, thanks to the advanced W-axis that retracts the torch when reaching the welding seam.

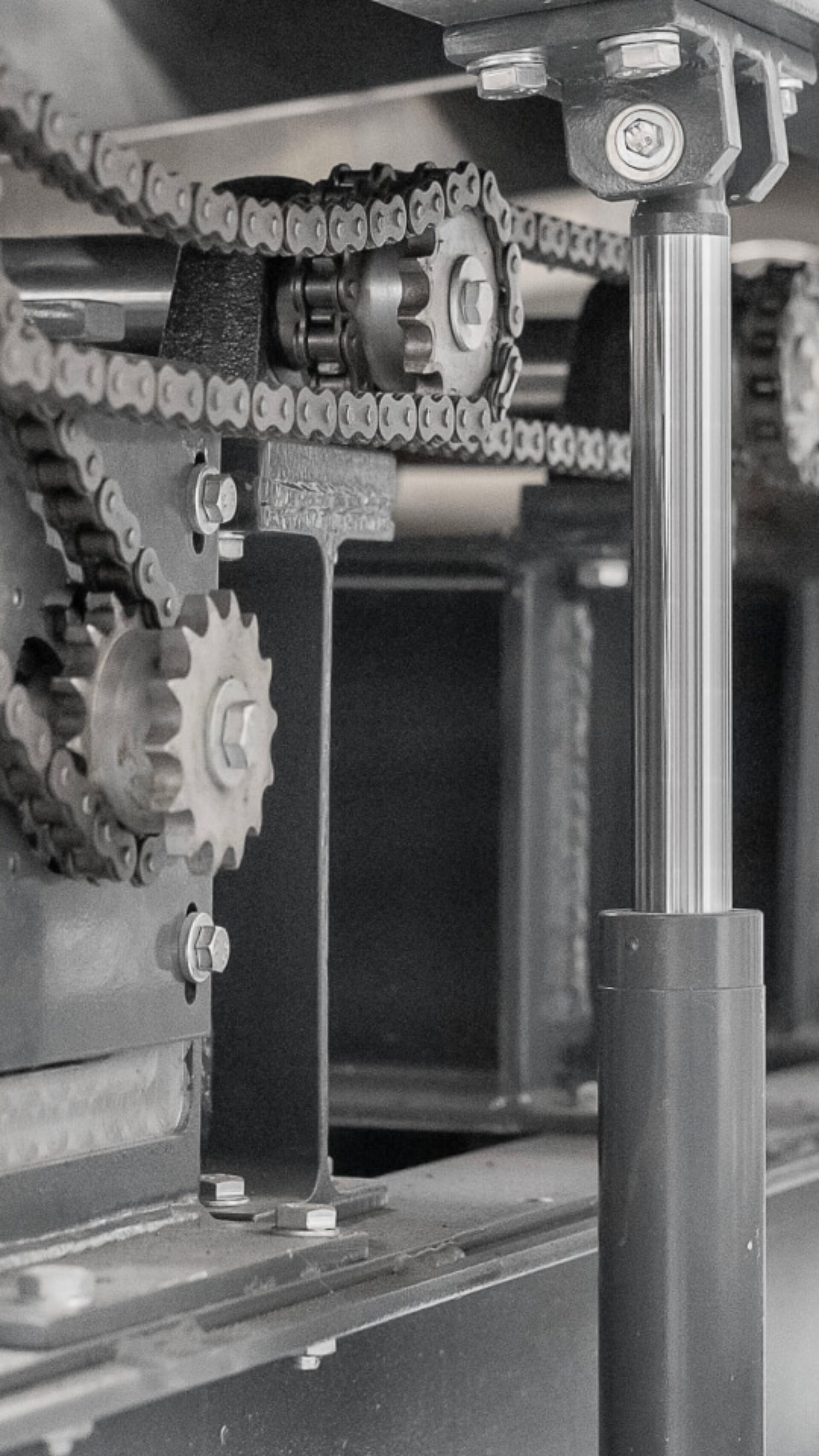

DURABLE CONSTRUCTION

Built with high-quality materials to withstand rigorous industrial use, ensuring long-term reliability.

ROBUST AZIMUTH TORCH HEAD

Provides exceptional stability and guidance for the cutting torch, resulting in high-quality, repeatable cuts.

BENEFITS

HIGH PRECISION EVERY TIME

Linear guiding systems and solid rack-and-pinion drives ensure accurate, repeatable cuts with minimal deviation.

COROBS

Most sophisticated software in the market for generating the required cutting shapes with various weld bevels.

SAVE SPACE

Designed to occupy minimal floor space, making it ideal for facilities with limited space.

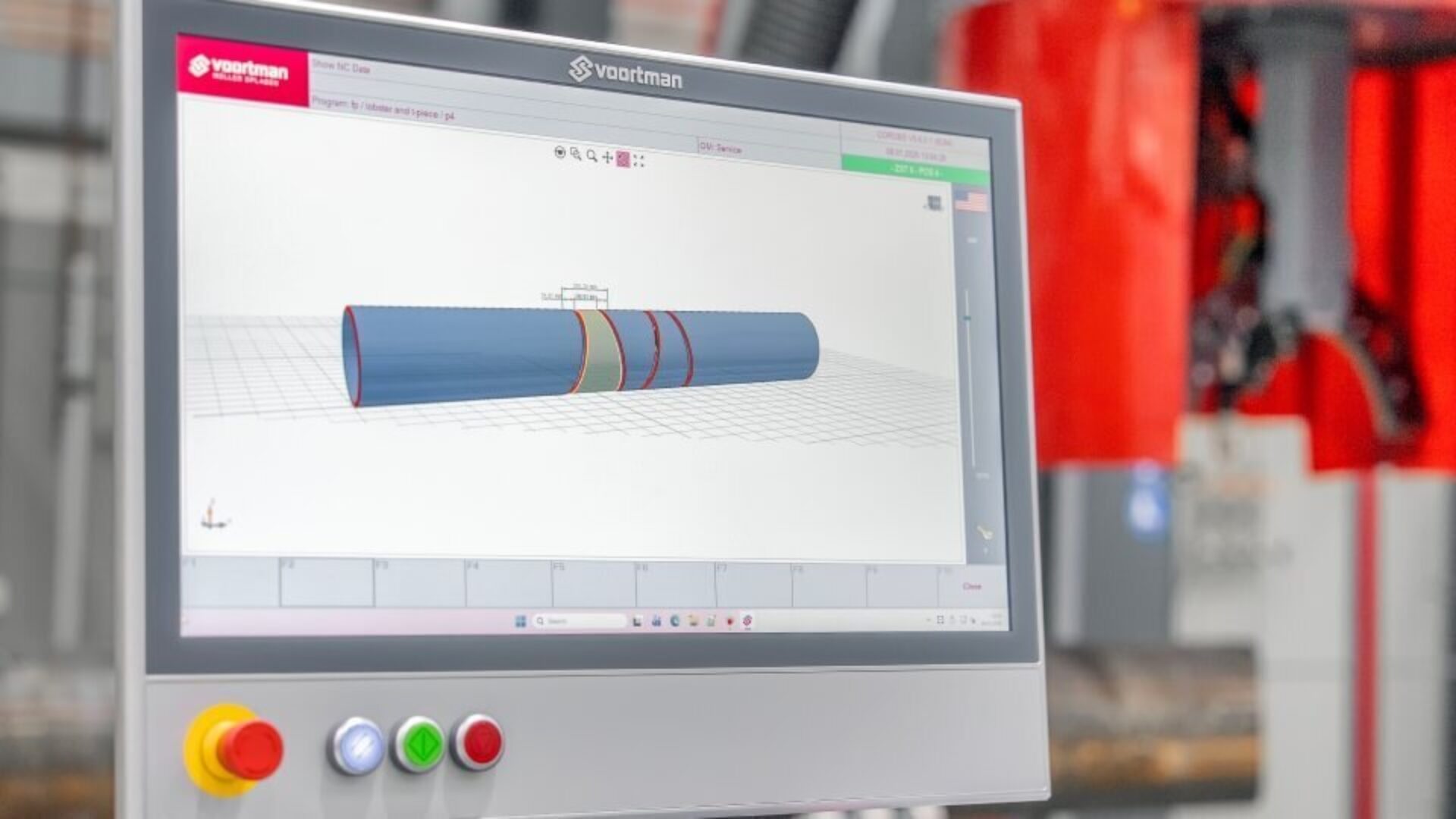

EASY TO OPERATE

The intuitive software interface shortens training time and simplifies daily operation for operators

SPECIFICATIONS

600

Min/Max Clamping

48 - 610 mm (1.9x24")

Max Workpiece Weight

4.000 kg

Installation Surface

9.000 x 4.000 x 3.500 mm (29.5x13.1x11.5ft)

900

Min/Max Clamping

48 - 914 mm (1.9x36")

Max Workpiece Weight

4.000 kg

Installation Surface

9.000 x 4.000 x 3.500 mm (29.5x13.1x11.5ft)

Need more information?

Get all the details you need; download free brochures, technical specifications, and product documents for this machine. Everything you need to make an informed decision is just a click away.

UPGRADE YOUR MACHINE

Logistics

Logistical assemblies such as loading rack, infeed conveyor, cutting conveyor, kick-off mechanism, off-loading rack, with freely selectable composition to reduce loading and unloading times in the machine for approximately 30% increase in productivity.

Industry-Specific Macro Packs (COMING SOON)

Choose from tailored macro sets designed for specific industries, with the flexibility to upgrade or expand as your needs evolve.

Dual Cutting Technology

Equip your machine with both plasma and oxy-fuel cutting capabilities for maximum versatility in material processing.

PypeServer Enterprise

The MO series comes standard with CorObs for on‑machine programming. You can add PypeServer Enterprise to import CAD files directly, automate features like saddles and O‑lets, and optimize material usage with advanced, defect‑aware nesting. PypeServer Enterprise also reports real‑time production updates to PypeServer Cloud, improving tracking and coordination.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

The Voortman MO pipe cutting machines support both plasma and oxy-fuel cutting. Plasma is ideal for thin to medium wall thicknesses with high speed and precision, while oxy-fuel is better suited for very thick wall pipes. In addition, oxy-fuel can cut at steeper angles than plasma, providing more flexibility for complex weld preparations. This ensures the right technology is available for each material and project.

Depending on the machine model, pipe diameters from 50 mm up to 4.000 mm can be processed. Lengths of up to 18 meters are supported. Plasma typically handles wall thicknesses up to 50 mm, while oxy-fuel can cut much thicker pipes. It’s important to note that the angle of the cut affects the effective cutting length, so wall thickness alone does not determine cutting time or capability, steeper bevels result in longer cuts. All common materials including carbon steel and stainless steel can be cut. These are widely used in offshore, shipbuilding, and construction all over the world.

The Voortman MO pipe cutting machines can produce a variety of holes, bevels, miters, saddles, dome cuts, and branch connections. The multi-axis torch motion allows for precise 3D profiles, ensuring pipes are ready for welding or assembly without extra manual work.

Bevel cutting is essential for welding preparation. It creates the correct edge angle and shape on the pipe end, ensuring strong, clean welds and reducing the need for additional grinding or manual preparation.

Yes, the Voortman MO pipe cutting machines are fully CNC-controlled and cutting programs are generated with our COROBS CAD/CAM software. COROBS optimizes cutting paths, automates torch movements, and minimizes operator input, making production faster and more consistent.

The Voortman MO pipe cutting machines provide a higher accuracy, repeatability, and productivity compared to manual methods. Complex geometries can be cut in a single setup, reducing material waste, saving time, and delivering consistent quality across all parts.