BE GROUP - Raising capacity and control with Voortman’s MSI line

“This is not about a single machine. It’s the complete solution. Hardware, software and material flow working together.”

Ilkka Kontkanen

Production Director, BE Group

Inspired by this testimonial?

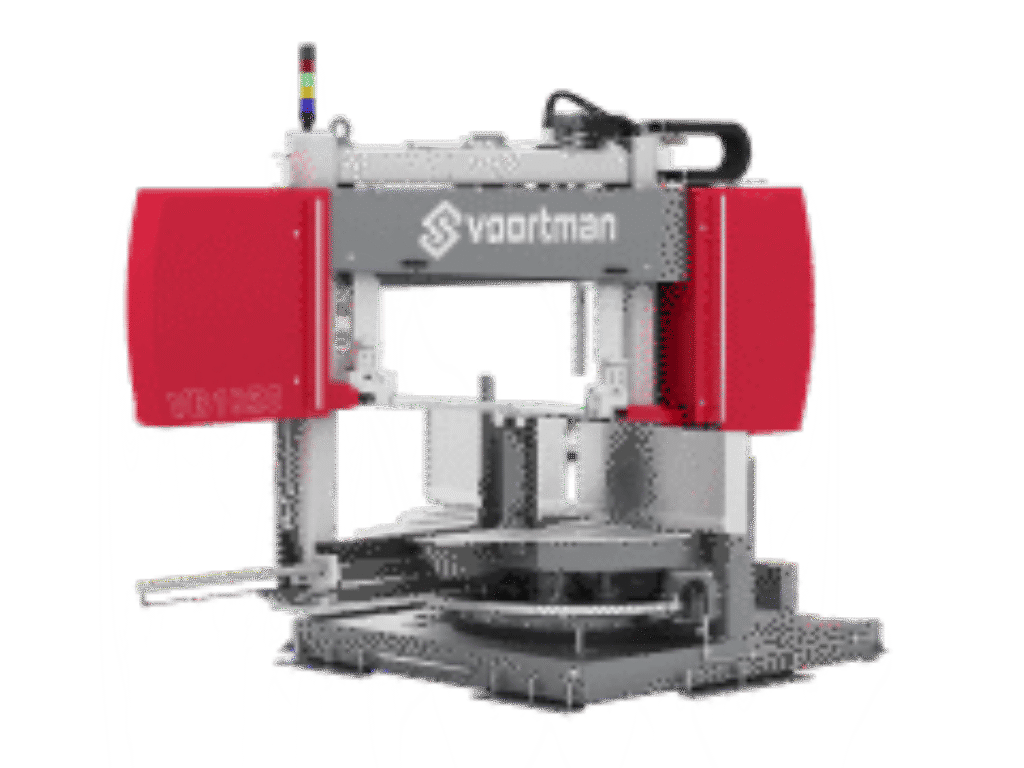

REFERENCED PRODUCTS

Multi System Integration (MSI) >>

Fully automated integrated production line.

Take control of your factory.

THE CHALLENGE

BE Group's old production line created dependencies that limited throughput. Operators manually keyed in lengths and drilling data, nesting was done at the machine, and each order required repeated lifting and repositioning of material. Variability in operator experience also affected quality and cycle times. “We were not able to provide our customers a solid promise for deliveries,” says Production Director Ilkka Kontkanen. The internal process simply could not support the flexibility customers expected.

BE Group needed not just new machinery, but a redesigned digital and material workflow. One that would remove manual inputs, stabilize production and support long-term growth.

ABOUT THE COMPANY

BE Group is one of the leading steel service companies in the Nordic region, with operations across Finland and Sweden. In Finland alone, the company employs around 270 people and runs multiple production units supported by an extensive sales network. Its role goes beyond steel distribution: BE Group combines warehousing, further processing and logistics to serve a wide range of industries with demanding schedules and specifications.

The company’s customer base spans from small fabrication shops to large-scale construction projects such as shopping centers, industrial facilities and data centers. This variety defines BE Group’s daily operations. Orders differ significantly in size, geometry and delivery urgency, requiring a production environment that can adapt quickly without compromising quality or reliability.

THE SOLUTION

Together with Voortman, BE Group refined nearly twenty layout iterations before finalizing a perfected line that minimizes lifting and maximizes continuous processing. Three band saws, a drilling unit and multi-zone in- and outfeeds allow any item from the warehouse to enter production with minimal handling. A key insight from the joint feasibility study was the impact of crane movements per hour, optimizing this became a driver for the final layout.

On the digital side, LogicSteel MRP became the backbone of the entire process. BE Group integrated it directly with their ERP through the system’s API framework, allowing nesting data, material lists and work orders to move automatically between ERP, LogicSteel MRP and the Voortman machines.

Integration Architect Jukka Kuosmanen describes the impact: “The nesting accuracy is one of the key features. LogicSteel MRP can combine multiple projects in one nest, optimize remnants and significantly reduce scrap.”

LogicSteel MRP maintains a live shadow inventory, tracks remnant availability and intigrates fully within BE Group's ERP system. It provides full machine feedback like machining times, completed parts and material usage back to the ERP automatically. This creates a closed data loop for planning, material control and pricing.

“After four years of planning, executing and developing this together, I can truly say Voortman was the right choice; the best possible choice for us. ”

Ilkka Kontkanen, Production Director

LogicSteel MRP provides planners with a structured, up-to-date view of stock and remnants, enabling them to prepare complete production packages in advance. These prepared plans reduce variability on the shop floor, improve material utilization and ensure that machine operations start with clear, validated instructions, without relying on manual decisions at the machine. The result is a more predictable, stable production process where planning quality directly supports machine performance.

NEW POSSIBILITIES

The combination of Voortman hardware, service and LogicSteel MRP has shifted BE Group from operator-driven processing to data-driven production. Material flows more consistently, nesting is automated, remnants are reused without manual tracking and consumables are always in stock. The production planner can prepare full-day nests directly in LogicSteel MRP, and operators no longer input any machining data by hand.

Late changes, which once caused major disruption, are now manageable thanks to BE Group’s paperless, LogicSteel MRP-controlled workflow. The paperless planning approach makes it possible to adjust production plans late in the process, reducing disruption during periods of high sales activity.

Looking ahead, BE Group plans to perfect automation using LogicSteel MRP as the central engine for a fully closed-loop model: customer design files transferred from ERP, processed in LogicSteel MRP, executed on Voortman equipment and returned with complete machining data for pricing and planning.

MORE TESTIMONIALS