Officially launched: The V325 for heavy plate processing

We are proud and excited to introduce you to the new V325 heavy plate processing machine, which is at the moment making its worldwide debut at the FabTech 2017 exhibition in Chicago, Illinois. The Voortman V325 plate processing machine is the newest addition to Voortman's proven plate processing machine product line.

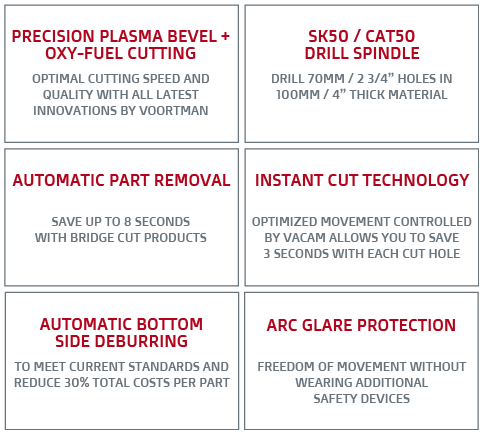

Unique features

With a massive drilling head and 20-tool automatic tool changer, the Voortman V325 is a must-have plate processing machine for every steel construction company. The V325 can process a wide variety of plates with thicknesses of 6 mm / 1/4” up to 100 mm / 4”. Carbide drilling up to 70 mm holes saves you an enormous amount of time over milling when processing heavy plates. 3D plasma bevel and oxy-fuel cutting guarantee high quality bevel cuts and weld preparations for instant assembly and welding.

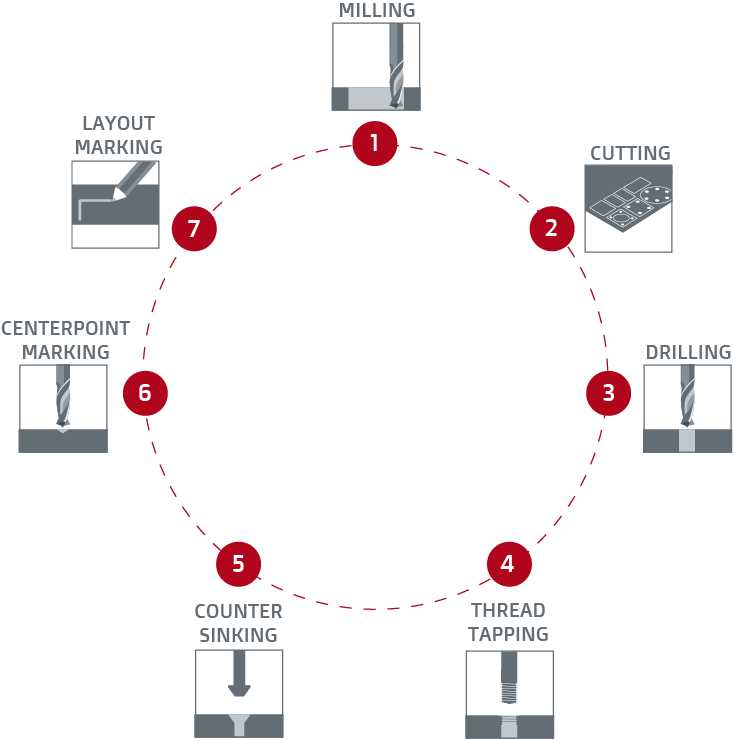

Processes

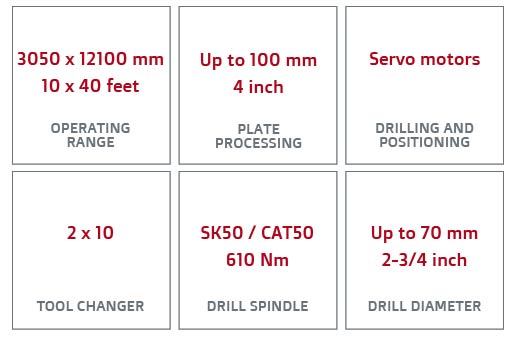

Specifications