NASCC 2024: The Steel Conference

Discover the Premier Automated Welding Solution for Structural Steel

We’re thrilled to share that we will once again be part of NASCC, this time unfolding in the city of San Antonio, Texas. Pay us a visit at booth 125 in exhibit halls 1 & 2 to meet the ultimate solution to the decreasing availability of skilled fitters and welders - the Voortman Fabricator.

🗓️ Date: March 20th to 22th, 2024

🌍 Location: San Antonio, Texas

🏢 Building: Exhibit Halls 1 & 2

📌 Booth: Booth 125 - Heavy Machinery Area

Should you have any inquiries before the event, please feel free to contact us.

Meet our automatic welding solution

Experience firsthand the incredible capabilities of this fully automatic welding solution during one of our live demonstrations at our booth. Our dedicated team of Voortman experts will be available at our booth to guide you through the remarkable capabilities of this groundbreaking automatic welding system.

Streamline Your Welding Projects with the Voortman Fabricator and DIGI-WELD

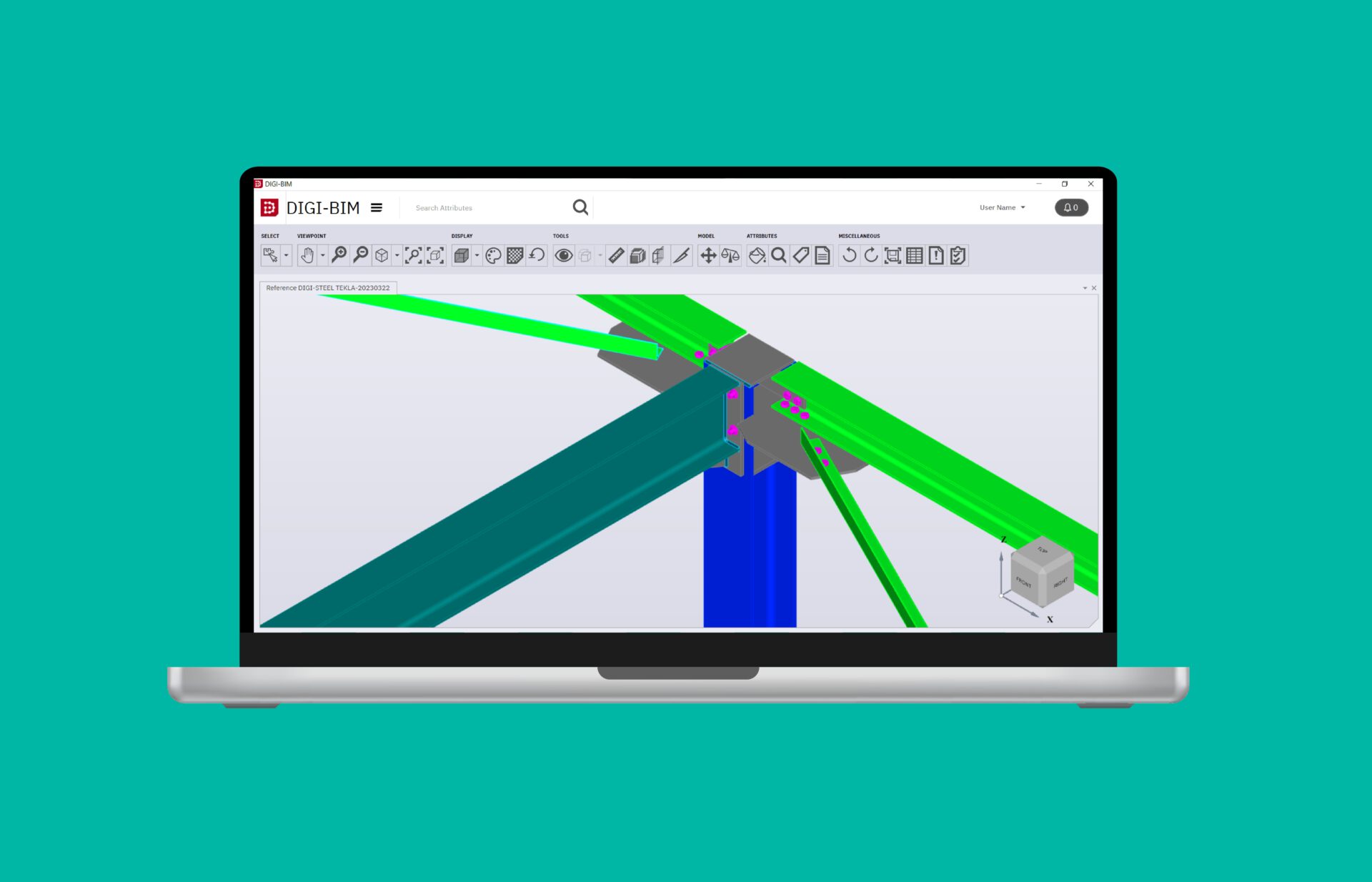

The Voortman Fabricator utilizes DIGI-WELD, our own cloud-based software which unlocks the potential of fully automatic welding ensuring precision and adhering to quality assurance standards. DIGI-WELD streamlines the welding process, as it provides automated weld checks and fixes, simplifying complex decision-making and assessment tasks often involved in welding.

DIGI-WELD detects and repairs missing, incomplete or incorrect weld data in the digital model, coming from detailing packages such as SDS2 and Tekla. With its ability to consider factors such as weight, size and torch accessibility, you can make informed choices between fully automatic welding, automatic fitting, or manual welding.