Introducing

The Voortman Fabricator

automated fitting and full-welding machine for the steel fabricating industry

ScrollYOUR SOLUTION TO THE SHORTAGE OF QUALIFIED WELDERS

The construction industry is witnessing rapidly changing market requirements, causing several increasing challenges for structural steel fabricators. The most frequently heard challenge is the pressing need to deliver projects on schedule in combination with consistently decreasing availability of skilled fitters and welders.

This is where The Voortman Fabricator comes in, a groundbreaking automatic welding system for structural steel.

Introducing the Voortman Fabricator

The Fabricator is the premier welding system for structural steel, whose flexibility lets you choose on-the-fly between Fit & Weld or only Fit. We offer the quickest turnarounds, maximum efficiency in space utilization and choice-based flexibility - that's what makes our ROI the fastest on the market.

- Ensure on-schedule project with reliable and flexible welding capacity;

- Access a flexible workhorse free from staffing constraints;

- Achieve consistent, high-quality welds, beat material tolerances;

- Secure the quickest return on investment in the market.

HIGH

EFFECTIVE ROI

Excels in speed, agility,

space utilization,

and effortless implementation.

SMALL

FOOTPRINT

Takes up significantly less space than manual welding

VERY

FLEXIBLE

Unlike

other systems,

The Fabricator offers

both fitting only and

full welding options

EASIEST IN

THE INDUSTRY

Comes

with

automated tools that

make work preparations

unbeatably simple

COMPACT DESIGN

AND SMALL FOOTPRINT

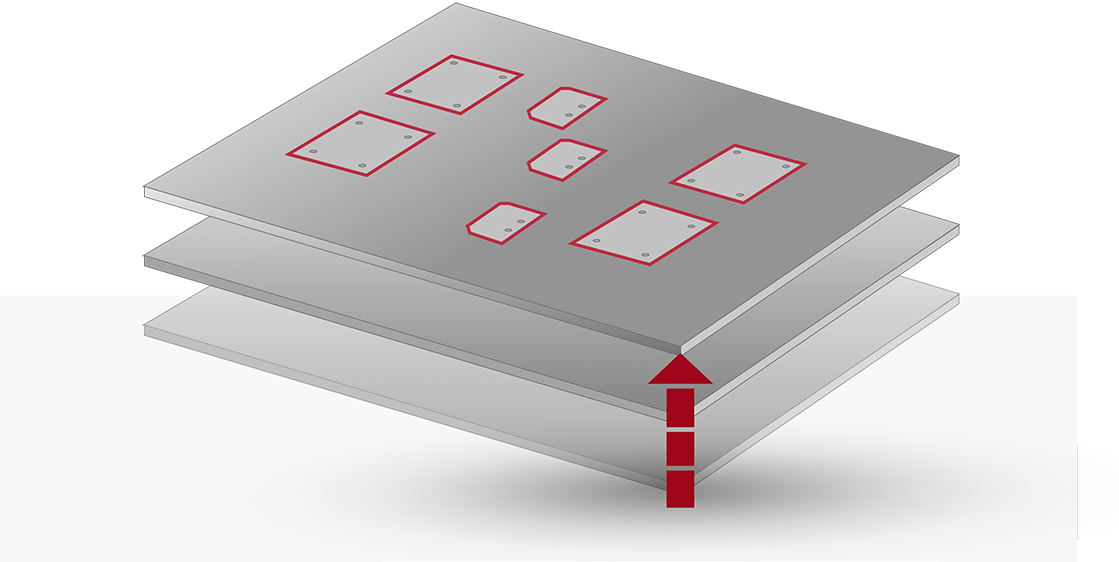

Meet the ultimate solution for structural steel fabricators looking to optimize their workspace and streamline their production processes. With its tracks conveniently positioned on one side, loading and unloading are simple to complete. The Fabricator is a space-saving system that fits easily, even in smaller workshops, thanks to its compact design and small footprint.

PROFILE LENGTHS UP

TO 80 FT. (24M)

Welding lengths of up to 24m (80 ft.) make it the ideal choice for handling large-scale welding projects. To ensure even more precision and flexibility, the tracks are exceeding the maximum welding length. This enables the robots to select an optimal track position for welding, while also avoiding singular positions. With this advanced feature, the Fabricator provides maximum efficiency and output, allowing for faster completion of projects while maintaining high-quality standards.

EASY TO OPERATE IN

ANY ENVIRONMENT

You can load with a forklift, side loader, or overhead crane, making it easy to

operate in any workshop. Choose the method that works best for your specific layout and needs.

FAST ROTATIONS FOR

MOST EFFICIENT FLOW

Designed to deliver efficient and reliable welding, makes this the ideal system for large

assemblies with multiple components. Robust main beam rotation allows for quick

movement between weld positions, ensuring a maximum number of parts are attached in less time - making this the most cost-effective choice.

"We believe that the work you save at the back end of your production should not be pushed to the front end. We are committed to upholding this principle by providing solutions designed to make sure it doesn't happen"

HENKJAN VOORTMAN - APPLICATION ENGINEER

IMPORT DATA INTO FABRICATOR CONTROL FROM AN OFFICE ENVIRONMENT

WITH NO VISIBLE INTERRUPTION FOR OPERATORS RUNNING MACHINES

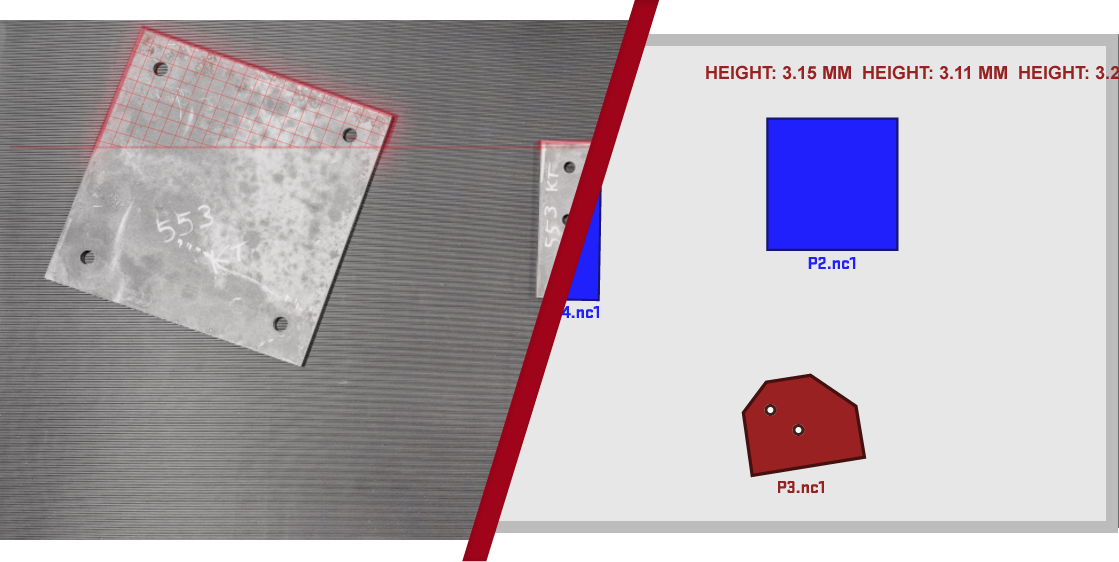

VALIDATE FROM THE OFFICE

Ensuring a high up-time with the Fabricator is key to achieving optimal ROI; limiting disruptions in production helps pave way for successful operation. With VACAM Office edition, work preparers can quickly import data into Fabricator control from an office environment with no visible interruption for operators running machines. The software validates imported information to guarantee everything is correct before it's processed - allowing your operator to press the button and walk away without any worries.

OPTIMIZED WELD PARAMETERS

VACAM office edition makes it easy to decide which assemblies should be produced on Fabricator. With its automated pre-check, VACAM will deliver a suitability percentage for each assembly imported and this info can even be exported and shared with external MRP software like DIGI-STEEL.

Assemblies ready for production on the Fabricator are released from VACAM Office and appear directly onto the VACAM control panel of the machine. The VACAM software ensures weld quality meets applicable standards by optimizing parameters to achieve desired results.

EVERY FABRICATOR SYSTEM INCLUDES HIGH END INDUSTRIAL COMPONENTS AND FEATURES:

- Industrial, 6-axis Panasonic arc welding robot

- Industrial, 6-axis Panasonic handling robot

- Single ‘One Side’ Robot track type;

- Build-in 450A welding power source type SP-Mag / Hyper Dip;

- Water cooled welding torch with quick disconnect system;

- Compressor cooling with temperature control;

- Mechanical torch cleaning unit;

- Wire Wizard package;

- Rotational positioners with hydraulic clamping. Payload up to 6.000 kg / 13.227 lbs. for 3 rotators;

- Track for (motor driven) positioners for optimal positioning and grounding;

- Automatic machine calibration;

- Automatic Tool Center Point calibration;

- Part table for positioning parts to be picked up by the handling robot;

- Complete safety according to UL /RIA;

- Autonomous weld path generation from 3-D engineering model till production;

- Work preparation software

CONSISTENCY, ROUND-THE-CLOCK

Its advanced optical sensor and powerful laser line projector deliver quality control and product recognition. Next to that, it's fast rotators guarantee the most efficient assembly order, and Panasonic's controller is renowned for being the fastest and most powerful model on the market. Welding paths are automatically generated by VACAM, allowing you to automate welding processes with ease and minimal human intervention.

ELIMINATE WAITING TIMES - MAXIMIZE UPTIME AND OUTPUT

With VACAM software controlling longitudinal positioning and swift beam rotation, you'll enjoy a production flow that is faster and more efficient than ever before. Plus, the Fabricator's clamping system eliminates the need for costly re-measuring. Panasonic's welding robot revolutionizes weld quality with its lightning-fast 250 times faster communication speed. Flexible notifications will alert operators of any issue so they can quickly address it without disrupting production.

WATCH NOW!

WEBINAR | ROAD TO SMART FACTORY

Reijrink and Voortman have formed a partnership to create a win-win situation. Reijrink is now able to automate its full production process with the arrival of the Fabricator. Voortman is utilizing this opportunity as a test for their machine, collecting data to expand system possibilities and increase production capacity.

Watch and learn from the steps they have taken. How do they deal with automation? What is the impact on personnel and work preparation?

VERY FLEXIBLE

Advanced robotics handle every step of production, from fitting add-on parts to full welding. This allows manual welders and assemblers to focus their energy on higher reward projects instead of routine duties. The Fabricator's versatility also enables it to scan, assemble and weld plates of all shapes and subassemblies with minimal effort. Plus, switch tables can easily be swapped for maximum efficiency during long production runs.

It scans for plate thicknesses, outside contours, and inside contours to ensure top-notch quality control as well as product recognition.

Switch tables can easily be swapped for maximum efficiency during long production runs.

MORE ON THE EXACT COMPONENTS AND FUNCTIONS

- The welding process is executed through unique integrated combination of robot, robot control, servo wire feed, and power source.

- The robot securely holds the weld torch and precisely performs each weld with accuracy.

- The

robot controller receives the specified weld paths from VACAM and translates

them into precise movements of the robot's axes, allowing for a smooth

transition between welding operations.

- The

welding source generates the precisely calibrated current and voltage that is

needed for a reliable welding result.

- A

transformer is used to convert the main supply voltage and frequency to the

appropriate values for powering the welding source and robot controller.

- During

the welding process, heat is partially absorbed by the torch, which is then

cooled by a cooling unit.

- A

Wire Wizard system utilizes wire cables, pneumatic feed assist, and the wire

guide modules to ensure a frictionless transport of the welding wire.

- A

mechanical cleaner ensures automated cleaning of the welding torch.

ENJOY THE EASE OF USE

Eliminate complex programming and training by using self-calibrating robots and automatic measurements, while its small footprint allows it to fit into any space. The Fabricator also offers a hassle-free loading process with laser guidance, so operators can stay in their vehicles. Plus, its rotators are easy to maintain for increased reliability and maximum uptime.