LOGICSTEEL CADCAM

Boost your CAD to CAM process

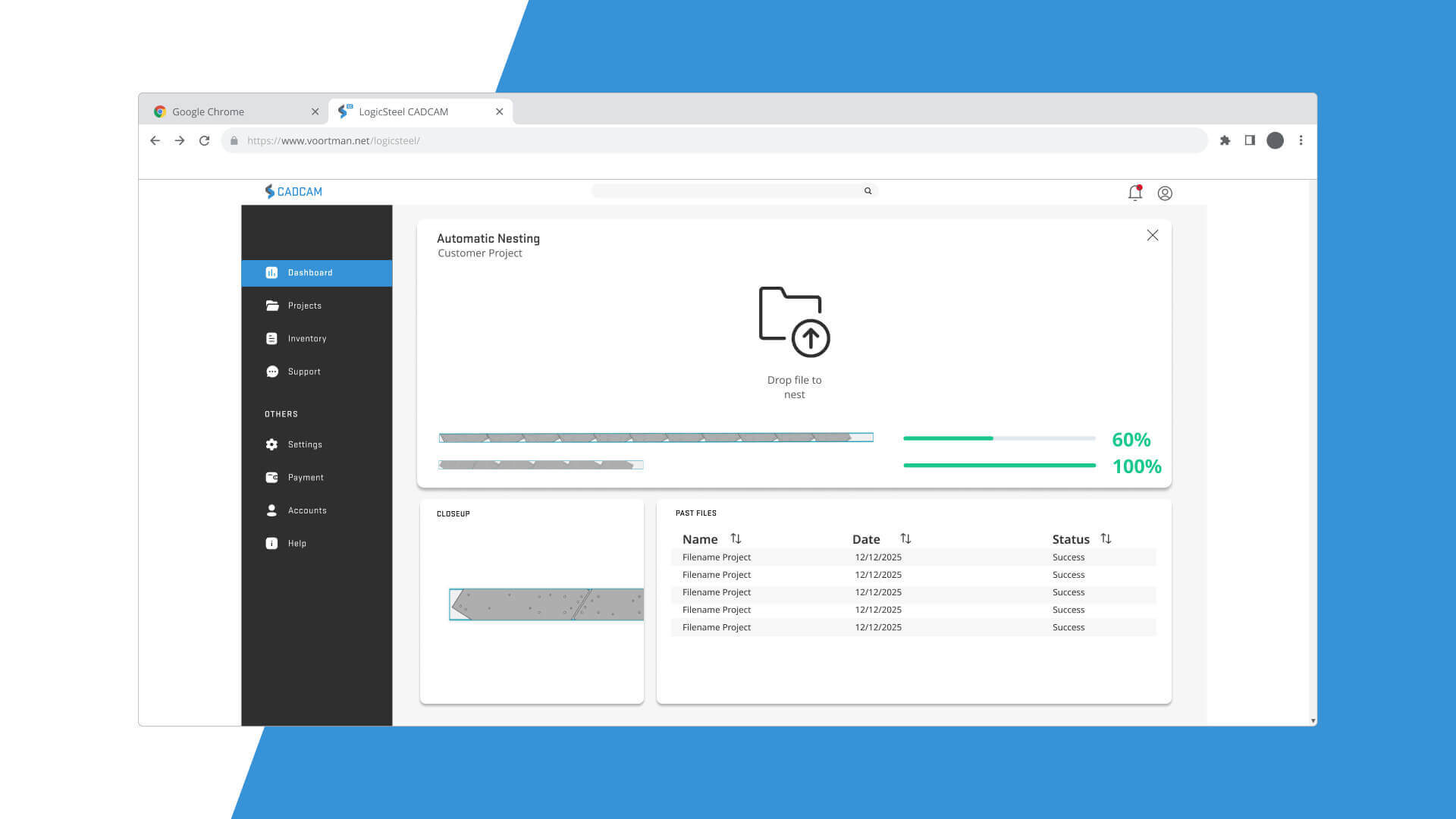

LogicSteel CADCAM boosts efficiency across the CAD to CAM process, saving time, reducing material waste, and minimizing manual input. Automatic issue resolution, auto nesting, NC file optimization and generation of machine-optimized instructions ensure a smooth and reliable workflow, supporting efficient, fast and high quality production.

GET QUOTE COMPARE SOFTWARE

HIGHLIGHTS

FASTER NESTING AND WELD PREP

LogicSteel boosts the CAD to CAM process by automating both nesting and weld preparation. Utilizing advanced algorithms to perform auto-nesting with market leading efficiency, it saves users time and reduces material waste. For welding preparation, LogicSteel takes models from Tekla and SDS2 and automatically resolves issues and refines weld data, allowing users to move from design to production faster, with less manual work and fewer delays.

GET QUOTE

OPTIMAL RESULTS

All output from LogicSteel is optimized specifically for Voortman machines, ensuring nests can always be executed and welds can always be performed without interruption. This deep integration guarantees that every part is production-ready, enabling smooth, reliable operation on Voortman machines.

INVENTORY

LogicSteel helps users stay in control of their material usage by integrating manual inventory tracking directly into the nesting process. Users can match available stock with nesting requirements, reducing over-ordering and minimizing waste. This ensures that production planning is more accurate, efficient, and cost-effective, especially when working with limited or high-value materials.

OUR CUSTOMERS

GROW YOUR BUSINESS WITH MODULES

PLATE WORK PREPARATION

Automatic nesting with inventory management for Voortman plate machines.

BEAM WORK PREPARATION

Automatic nesting with inventory management for Voortman beam machines.

PIPE WORK PREPARATION

Automatic nesting with inventory management for Voortman MO machines.

WELD WORK PREPARATION

Automatic generation of welding instructions for the Voortman Fabricator.

QUESTIONS?

We are happy to help!

If you have any questions about LogicSteel CADCAM or need help finding the right solution for your business, feel free to get in touch with us directly. For quick answers to common questions, check out the frequently asked questions below, where we’ve compiled a list of the questions we receive most often.

LogicSteel CADCAM is designed to boost efficiency across the CAD to CAM process by automating key steps such as nesting and weld preparation, resolving issues from Tekla and SDS2 models, and generating machine-optimized instructions for Voortman machines. It reduces manual input, saves time and material, and integrates inventory tracking to match available stock with nesting needs, ensuring fast, reliable, and high-quality production.

We are constantly developing new features for LogicSteel CADCAM, and with over the air updates you get new features and fixes right away, without long wait times.

No. LogicSteel CADCAM is fully hosted in the cloud, meaning you have access from anywhere, anytime and on any device.

No. With LogicSteel CADCAM you pay for what you use, not for an account or user.

With LogicSteel CADCAM you get the full support of the Voortman customer service team, who have dedicated support for LogicSteel users. This means there is someone available around the clock to help you when needed.