V320

PLATE PROCESSING MACHINE

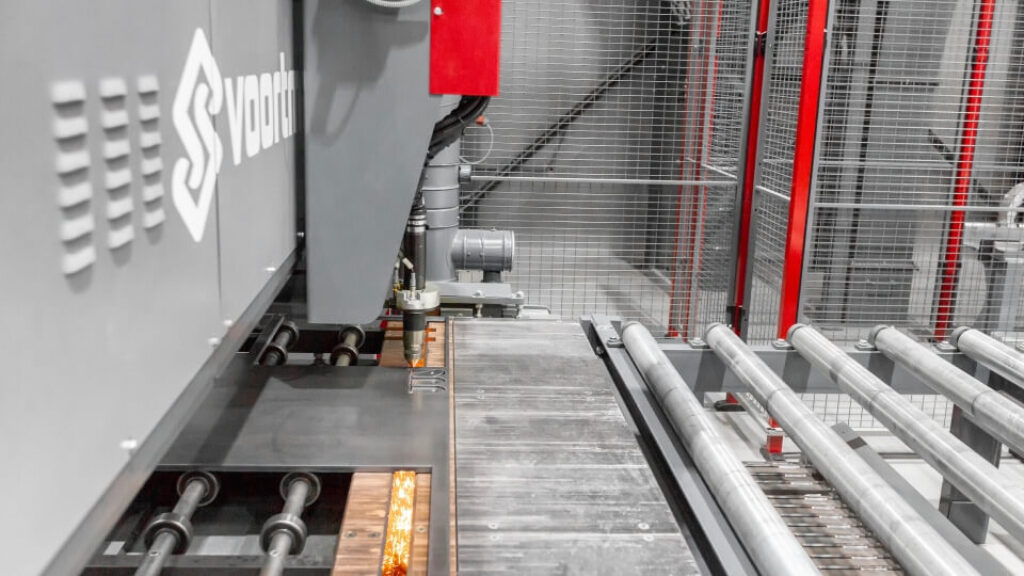

Engineered for precision and productivity, the V320 combines drilling and advanced plasma cutting technology with automated material handling to deliver efficient, accurate plate processing.

- Maximize productivity with long, unattended shifts featuring automated tool changes and seamless parts discharge.

- Save time and floor space by combining drilling and plasma cutting in a single, integrated system.

- Reduce material waste and costs through advanced nesting technology and minimized dead zones.

- Make smarter decisions with a real-time dashboard that delivers job progress and performance insights.

- Prevent downtime during extended runs with automatic swarf removal that keeps the cutting area clean.

Available models:

2.000 x 6.000 mm | 2.000 x 9.000 mm | 2.000 x 12.000 mm

3.000 x 6.000 mm | 3.000 x 9.000 mm | 3.000 x 12.000 mm

OVERVIEW

The V320 is an integrated plate processing system combining high-torque drilling and advanced plasma cutting within a single automated platform. Equipped with a 10-station tool changer, magnetic torch mounts, and intelligent nesting algorithms, it ensures precise hole creation, optimized cutting paths, and minimal material waste. Automated swarf removal, collision-safe design, and resume cutting functionality deliver continuous operation and consistent quality across varying plate thicknesses.

MACHINES IN THIS PRODUCT LINE

SUCCESS STORIES

We deeply value our customers and their feedback; it's what drives us to keep improving and innovating. Curious how our machines make a difference? Hear directly from our customers as they share their experiences.

APPLICATIONS

FEATURES

AUTOMATIC TOOL CHANGER

A 10-position tool station eliminates manual intervention between drilling operations, reducing downtime and labour costs. This means higher throughput and less operator dependency which is critical in high-volume or unmanned production environments.

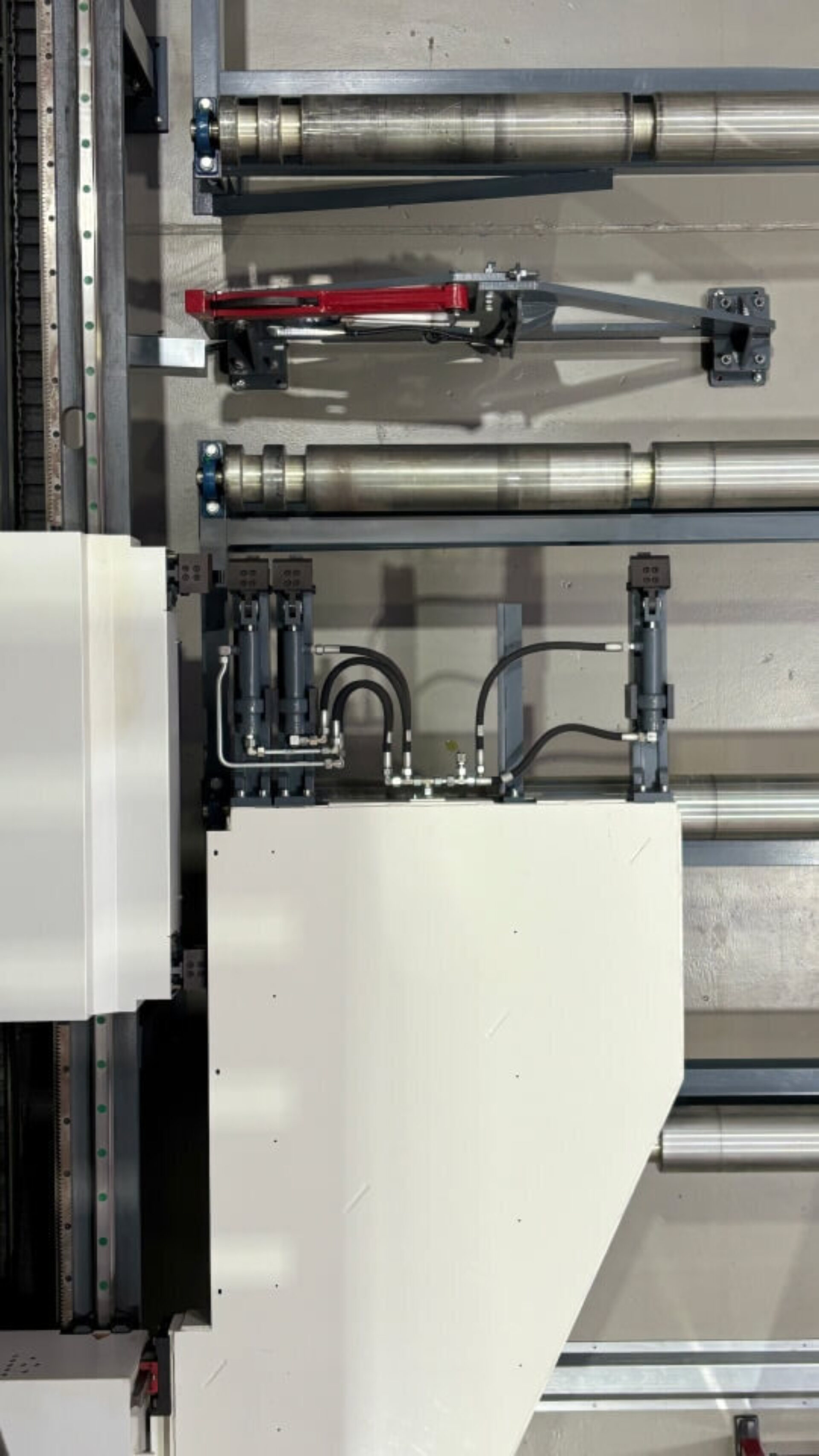

ROBUST GRIPPER TRUCK SYSTEM

Strong backside and supporting side carriages - accurate plate positioning and secure clamping minimize dead zones and maximize material yield. This translates into lower material waste and better nesting efficiency, which is a major cost-saving factor for fabrication shops.

MAGNETIC TORCH MOUNTING

Collisions are inevitable in plasma cutting. This feature prevents damage and removes the need for recalibration, saving hours of maintenance and avoiding expensive component replacements; key for uptime and operational continuity.

BENEFITS

REDUCED DEAD ZONE

By releasing the side gripper in the final processing stage, the V320 cuts between gripper clamps and across the full plate, minimizing dead zones and increasing material utilization.

CONVEYOR & DROP DOOR

A 750 mm-wide conveyor transports products up to 500 mm diagonally, while the heavy drop door table rapidly unloads parts to 500 × 500 mm and 75 kg, accelerating discharge cycles and enabling extended unmanned runs.

SWARF REMOVAL

A dual‑action swarf brush first swipes the plate clean, then executes a second pass to brush away any chips, so plasma doesn’t cut over debris – preventing defects and improving cut consistency.

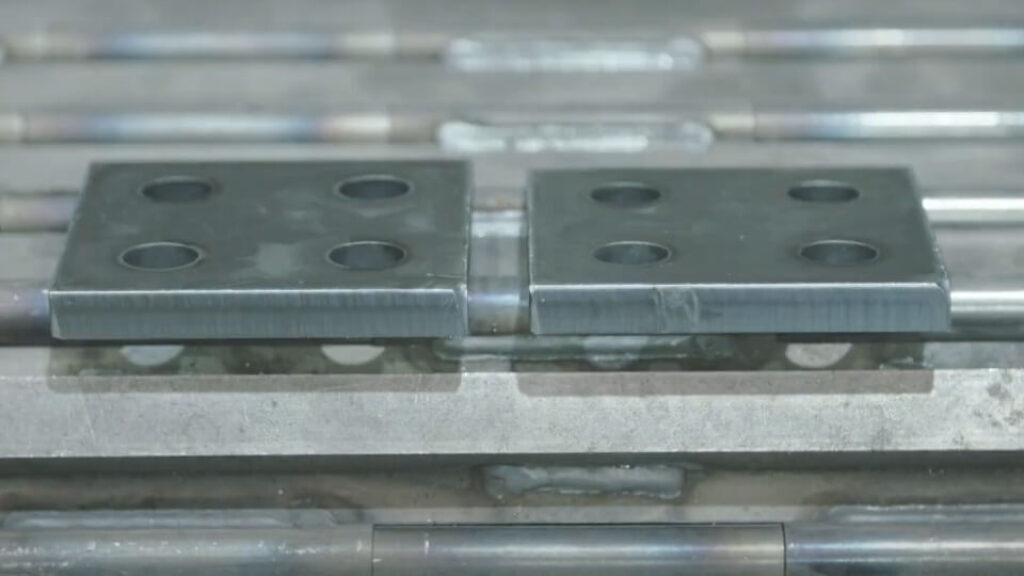

RIGID CLAMPING

High‑stability drill clamps suppress vibration so the high‑torque spindle can apply full power, preventing tip damage and chatter while improving hole quality and tool life.

BRIDGE CUTTING

Nesting bridge cuts discharge full rows at once, reduce plasma restarts and pierces, and save up to 8 seconds per product – lowering consumable costs and improving yield.

HD MULTIDROP WORKFLOW

A sequential multi‑drop strategy maximizes utilisation of the plate skeleton while cutting fewer metres, lowering waste and operating costs and reducing material handling.

REMNANT NESTING

Plate Verification with laser contour tracing and VACAM auto‑rotation lets you nest into remnants using a single intact corner, reducing material waste and setup time.

RESUME CUTTING

An easy UI restarts interrupted cuts exactly at the error point with near‑invisible marks, minimizing downtime and preserving cut quality.

DOWNLOAD SPECIFICATIONS

2000

Operating Range Width

2.050 mm

Maximum Plate Weight

7.500 kg

3000

Operating Range Width

3.050 mm

Maximum Plate Weight

9.000 kg

UPGRADE YOUR MACHINE

Hydraulic Pushers

Infeed‑mounted hydraulic pushers retract the plate to the datum line at the push of a button, delivering fast, repeatable alignment and shorter setup time.

Cross Buffer

Manually controlled cross transports provide an infeed buffer and expand per meter, smoothing loading and reducing stoppages.

Hypertherm Plasma Sources

Choose XPR300 or XPR460 sources to boost cutting speed and maintain clean edges on thicker materials.

Layout Marking Tool

CNC‑controlled scribing of part numbers and reference lines ensures consistent marks, faster setup, and fewer mix‑ups on the shop floor.

Outfeed Roller Conveyor

It can be lengthened with 1,5 meter to accommodate larger left-over plate skeletons and big plates that cannot be unloaded automatically and need to be unloaded manually. The outfeed length determines the maximum product length and thus can be 1,5m or 3m.

Load Manager Module

With the SigmaNEST Load Manager module, you have full control over complex work orders, production can be assessed quickly and orders can be easily assigned to any compatible machine.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

Enable the Dross Inhibitor for plasma piercing. Just before the pierce, the system sprays a thin oil layer onto the material; the “volcanic” burst of molten metal during piercing hits this layer and bounces off instead of sticking to the plate, which dramatically reduces splash and dross around the pierce point and lowers post‑processing time.

A stress‑relieved, thermally and mechanically treated gantry is a rigid base, equipped with precision linear guides and preloaded ball screws; paired with direct‑drive servos, high‑resolution encoders, automatic lubrication, and environmental protection, the system preserves geometry, minimizes wear, and keeps tolerances tight year after year.

Voortman offers remote diagnostics, preventive maintenance packages and full service assistance. Most issues can be solved remotely through the machine interface, reducing downtime and service costs. Spare parts are stocked regionally, ensuring fast response when physical intervention is required.

High‑quality cutting requires frequent height measurements; in a typical part with four holes, over 30% of cycle time can be spent on movement-related checks. Our ultra‑fast height control minimizes this overhead, letting you tune measurement frequency to the desired quality and unlocking the maximum achievable production time. Thanks to magnetic mounting, the oxy‑fuel torch shares the same fast height control, so both plasma and oxy‑fuel benefit from higher throughput with consistent cut quality.

Use VACAM’s live counters for start‑stop counts and total cutting length, to set change intervals that match your quality targets. This keeps cut quality consistent, prevents premature change‑outs, reduces scrap and rework, and lowers your cost per part while maximizing uptime.

The Voortman V320 combines a rigid pass‑through architecture with a high‑power drill spindle and servo‑driven precision motion, so it can push larger carbide tools at higher feed rates while keeping hole quality and position tolerance tight. Specifically, it uses a 40 HP drilling spindle capable of up to 2,500 rpm, paired with servo drives and precision ball‑screw positioning for fast, stable Z‑axis feeds; exactly what you need for heavy plates and rapid cycles.