Steel fabricators & Metal Fabricators

Transform your business with Voortman

In the current steel and metal fabrication industry, finding skilled labor is increasingly challenging. Therefore, to remain competitive and ensure long-term success, it is crucial to prioritize automation, maximize output, and maintain flexibility. Rely on Voortman's wide range of reliable solutions to support you through this optimization journey.

Below you'll find more info on:

1. Achieving maximum output through automation.

2. Reducing man-hours through automated welding.

3. Enhancing processing flexibility.

1. ACHIEVING MAXIMUM OUTPUT

THROUGH AUTOMATION

Given the narrow profit margins steel fabricators and metal fabricators are dealing with, there's a need to prioritize speed and efficiency, making automation a key driver to increase their earnings. With Voortman's state-of-the-art automation technologies, you can unlock maximum

output potential and minimize manual intervention. Moreover, by automating repetitive tasks, you can free up your workforce to focus on more complex and

valuable jobs in the workshop. Let the machines handle the routine tasks while

you achieve improved overall performance.

Explore the following noteworthy

automation solutions.

2. REDUCING MAN-HOURS

THROUGH AUTOMATED WELDING

The shortage of technical personnel is a growing problem in the industry. In welding and assembling particularly, the situation is difficult. We frequently hear from the market that when manual production transitions to automated production, bottlenecks shift. In fact, assembly and welding becomes the bottleneck, requiring the most manpower, particularly skilled welders.

Designed to help overcome this challenge is the Voortman Fabricator! More than a machine, it's an innovative welding system that provides flexibility for structural steel fabricators to easily choose between fitting or fitting & full-welding. This premier system, powered by innovative cloud software, automates work preparation and efficiently prepares complete models rather than individual assemblies. By automating welding tasks for steel profiles, plates, angle irons, tubes, U-profiles, and crane runway consoles, it eliminates the need for manual labor and improves the quality of your projects.

But wait! The

Voortman Fabricator is your co-worker and facilitates your workforce to work on

more complex tasks that demand human expertise.

Ready to level up your workshop and simplify your welding work?

3. ENHANCING PROCESSING FLEXIBILITY

FOR STEEL FABRICATORS AND METAL FABRICATORS

Fabricating miscellaneous metal constructions like balconies, stairs, railings, landings, and industrial constructions entails diverse operations in smaller quantities. Therefore, it's crucial to have flexibility

and high-quality output when it comes to efficient plate- and beam processing. Voortman machinery and software are designed to optimize processing flexibility, letting you adapt swiftly and seamlessly to varying project requirements, while boosting your fabrication shop's consistency, productivity, and output.

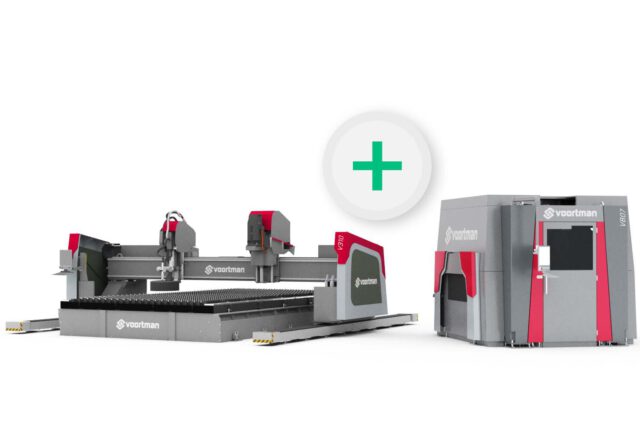

For example, combining two all-in-one machines, the Voortman V310 plate processing machine and the Voortman V807 robotic coper, you can tackle any construction job on a small footprint.

The V310 offers unparalleled flexibility in a concise area, allowing you to mill, drill and bevel cut any product with exceptional accuracy at the push of a button. Its advanced software provides valuable feedback and enables you to cluster jobs, buffer multiple plates and run unmanned. With the V807 robotic coper, you can create copes, bolt holes, slots, notches, bevels, weld preps and layout markings in one pass with fast and precise results on all four material sides.

Whether used independently or in combination, these versatile machines offer:

- Ultimate flexibility

- Quick return on investment

- Full control over your workshop's output